|

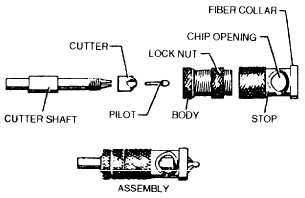

Machine Countersink Machine countersinking is used to flush rivet sheets

0.064 of an inch and greater in thickness. A countersink

has a cutting face beveled to the angle of the

rivet head, and is kept centered by a pilot shaft inserted

in the rivet hole. When a conventional countersink

is used, you should try each hole with a rivet

or screw to ensure the hole has not been countersunk

too deeply. The adjustable countersink is the

best tool to use because the depth of the hole can be

controlled. A stopping device automatically acts as a

depth gauge so that the hole will not be countersunk too

deep. Figure 13-7 shows an adjustable stop countersink.

The countersink should always be equipped with a

fiber collar to prevent marring of the metal surface. A

drill motor or hand drill (electric or air) maybe used to

operate the countersink. However, it should not be operated

above 2,500 rpm. The countersink must be sharp

to avoid vibration and chatter.

Figure 13-6.Skin fasteners.

Figure 13-7.-Adjustable stop

countersink.

|

|