|

PROCEDURES.

When failure

occurs in a flexible hose equipped

with swaged end fittings, the unit

is generally replaced without attempting a repair. The

correct length of hose, complete with factory-installed

end fittings, is drawn from supply. When

failures occur in hose assemblies equipped with

reusable style end fittings, the fabrication of the replacement

unit is the function of the intermediate and

depot organization levels. Undamaged end fittings

on the old length of hose maybe removed and reused;

otherwise, new fittings must be drawn from supply

along with a sufficient length of hose. The

following assembly procedures are for instructional

purposes only. When fabricating hose assemblies,

refer to the The

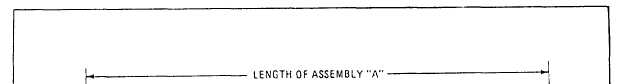

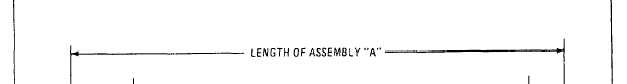

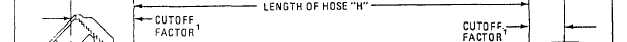

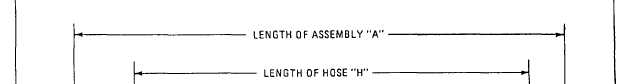

first step is to determine the necessary hose length

from table 5-2 and figure 5-10. Wrap the circumference

of the hose with masking or plastic electrical

tape at the cutoff to prevent flare-out of braid

if the hose outer cover is wire braid. Hose with rubber

or fabric outer cover does not require wrapping

Table 5-2.Hose Cutoff Factor

(In Inches)

Figure

5-10.Determining hose assembly length.

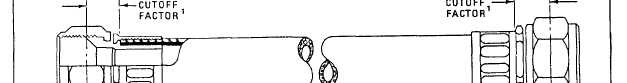

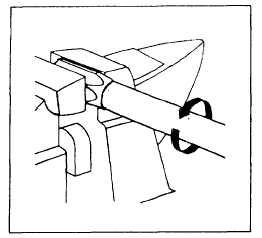

Figure 5-11.Hose insertion.

with tape. Measure the hose to the required length and

cutoff the square, using the cutoff machine (fig.

5-7). Blow the hose clean with filtered shop air after

cutting. Remove the tape and the clamp socket in

a vise (fig. 5-11). Do not overtighten vise on thin-walled

lightweight fittings. Screw the hose counterclockwise

into the socket using a twisting, pushing

motion until the hose bottoms on the socket shoulder.

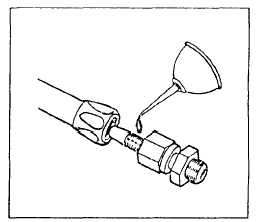

Back the hose out 1/4 turn. Assemble the nipple

and nut with a standard adapter of the same size

and thread (fig. 5-12). Lubricate the inside bore of

the hose and the outside surface of the nipple with hydraulic

fluid, MIL-H-5606, MIL-H-83282, or MIL-H-6083

(fig. 5-13). Clamp the socket with the hose

into a vise. Insert the nipple assembly into the hose

and socket by using a wrench on the hex of the

Figure

5-12.Nipple and nut assembly.

Figure

5-13.Assembly lubrication.

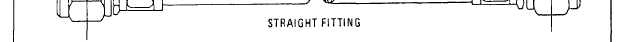

insertion tool. Turn the nipple assembly clockwise until

the nut-to-socket gap is between 0.005 and 0.031 inch.

The gap allows the nut to turn freely about its axis

(fig. 5-14). Remove the insertion tool from the assembly.

Repeat the procedure for hose assemblies with

straight fittings on both ends.

|

|