|

Proof Pressure Testing Hose assemblies must be proof pressure tested after

fabrication. Ballistic and oxygen hose assemblies

must be cleaned and tested by qualified aviation

equipment personnel in accordance with NAVAIR

13-1-6-4 before installation in weapons systems.

Observe all safety rules when you proof pressure test

hose assemblies, and proceed as follows to proof pressure

test hose assemblies. Clean hose assembly.

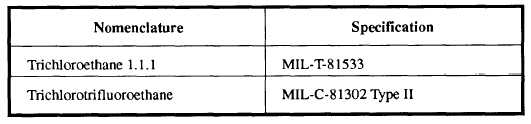

Table 5-3.Alternate Cleaning

Fluids for Teflon Hose or Hose Assemblies

Select test media from table 5-4. Select proof pressure.

See table 5-5, which is a section of the typical

hose assembly proof pressure test data sheet. Test

one hose assembly at a time. Several hose assemblies

that require the same proof pressures may be

tested together, if they are connected in series with adapters.

Unless otherwise directed, a manifold hose assembly

that contains different sizes or types of hose will

be tested at the lowest proof pressure required by any

one size or type contained in the manifold. Arrange

hose assemblies as close to the horizontal position

as possible. Allow trapped air to escape when

testing hose assemblies in a liquid test medium. When

testing an air or gas medium, test hose assemblies

underwater so that trapped air can escape from

the hoses braided outer covers. Hose assemblies

with a firesleeve do not require the underwater

test. Tighten the pressure cap. Apply proof

pressure for a minimum of 30 seconds, but no longer

than 5 minutes. Check leakage while maintaining

proof pressure.

After the completion of the proof pressure test, drain

the hose assembly and clean. Install the protective

closures. Install the identification tag. Prepare

the hose assembly for installation or storage.

|

|