REFRIGERATION UNIT CHECK VALVE.- The refrigeration unit check valve (fig. 4-7, detail A) is an insert-type check valve with a split flapper spring-loaded in the closed position. The valve, which is installed in the refrigeration unit to prevent hot bleed air from entering directly into the turbine, is located in a tee arrangement in the system just downstream of an orifice.

Icing of the water separator will occur only at low altitudes where mass airflow and temperature are relatively high. Only a small amount of high-temperature air is required through the orifice to melt such a deposit. However, at high altitude where the mass flow and bleed-air temperatures are low, the refrigeration pack lowlimit control operates to open the nonice and lowlimit control valve. When the nonice and low-limit control valve is open, high differential pressure across the bleed-air orifice permits the refrigeration unit check valve to open. This allows intermediate-temperature air to bypass the turbine, and thereby maintain water separator temperature above 0F. (See figure 4-6.)

CABIN AIR/WATER SEPARATOR, CO-ALESCER CONE, AND COALESCER BAG.-

The water separator is a welded cylindrical aluminum container installed downstream from the turbine and fan assembly. Its purpose is to remove a portion of the moisture condensed during the air-expansion process within the expansion turbine. (See figure 4-6.) The water separator container holds a coalescer bag, which collects the finely dispersed fog-like moisture discharged from the turbine. The wet air flows through the coalescer cone and through louvered swirl vanes to cause the heavier water particles to be deposited by centrifugal force against the outer surface of the collector section. Accumulated water is drained through the sump in the bottom of the collector section. The partially dried air then leaves the water separator by way of the air outlet duct. The coalescer bag may be removed for cleaning through an access cover secured with a quick-disconnect band coupling to the water separator shell.

WATER SEPARATOR ICE SCREEN.- An ice screen is located in the discharge end of the water separator to collect ice when moisturized airflow temperature is below the dew point temperature, or below 32F. The condensed ice crystals gathered across the ice screen cause a pressure differential, which is sensed by the nonice and low-limit control valve. The nonice and lowlimit control valve then increases the warm air supply through the mixing muff, the coalescer bag, and to the ice screen to melt collected ice.

WATER SEPARATOR BYPASS VALVE.- The bypass valve is a spring-loaded valve mounted in the water separator container. A failure of the nonice and low-limit control valve could cause ice particles to build up in the water separator coalescer bag. This ice would block the cabin air system. To ensure that air is supplied to the cabin, the water separator bypass valve allows turbine air to bypass the coalescer bag.

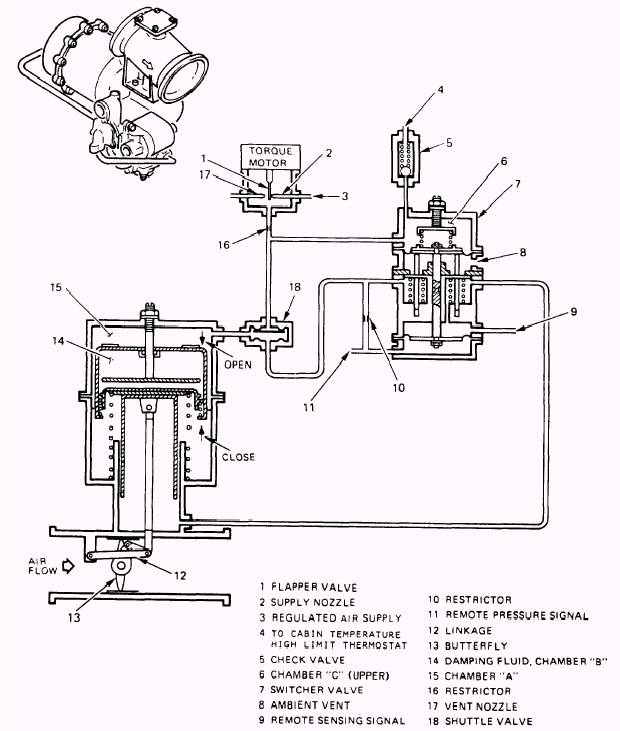

Figure 4-8.-Nonicing and low-limit control modulating valve schematic.