BRAKE SWITCHES AND CONTROL VALVES There are several types of switches and control valves used in hydraulic brake systems. Switches are normally safety devices. and there are two types used- the stoplight switch and the braking warning light switch. Control valves regulate pressure within the braking system, and there are three types- the metering valve, the proportioning valve. and the combination valve.

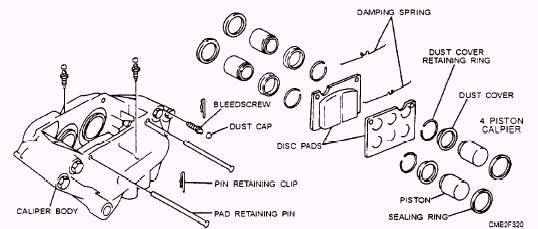

Figure 7-19.- Fixed multipiston caliper.

Stoplight Switch

The stoplight switch is a spring-loaded electrical switch that operates the rear brake lights of the vehicle. Most modern vehicles use a mechanical switch on the brake pedal mechanism. The switch is normally open, and when the brake pedal is depressed, the switch closes and turns on the brake lights.

On some older vehicles you may find hydraulically operated stoplight switches. In this system, brake pressure acts on a switch diaphragm, which closes the switch to turn on the brake lights.

NOTE

Brake light circuits are covered in chapter 2 of this TRAMAN.

Brake Warning Light Switch

The brake Learning light switch, also called the pressure differential valve, warns the operator of a pressure loss on one side of a dual brake system. If a leak develops in either the primary or secondary brake system. unequal pressure acts on each side of the warning light piston, moving the piston to one side thereby grounding the switch.

Metering Valve

The metering valve is designed to equalize braking action at each wheel during light brake applications. A metering valve is used on vehicles with front disc brakes and rear drum brakes and is located in the line to the disc brakes. The metering valve functions by preventing the disc brakes from applying until approximately 75 to 135 psi has built up in the system.

Proportioning Valve

The proportioning valve also equalizes braking action with front disc brakes and rear drum brakes. It is located in the brake line to the rear brakes. The function of the proportioning valve is to limit pressure to the rear brakes when high pressure is required to apply the front disc. This prevents rear wheel lockup and skidding during heavy brake applications.

Combination Valve

The combination valve (fig. 7-20) combines several valve functions into a single assembly. It functions as a-

Metering valve- holds off front disc braking until the rear drum brakes make contact with the drums.

Proportioning valve- improves front to rear brake balance at high deceleration by reducing rear brake pressure to delay rear wheel skid.

Brake light warning switch (pressure differential valve)- lights a dash-warning lamp if either front or rear brake systems fail.