TIRE REPAIR

Leaks from a tubeless tire are located by filling the tire with air and then placing the tire in a drum full of water. Bubbles will show the location of any leaks. If a drum of water is not available, coat the tire with soapy water. Soap bubbles will show the location of the leak. It has been common practice to attempt the repair of some punctures without dismounting the tire through the use of a rubber plug. However. this practice is NO LONGER RECOMMENDED, because of serious safety concerns. Using a plug to attempt tire repair without dismounting is effective only 80 percent of the time. The remaining 20 percent of such repairs will result in TIRE FAILURE, which may take the form of a dangerous sudden deflation (blowout).

The safe and correct procedure for tire repair is to ALWAYS remove the tire from the wheel and make the repairs from the inside of the tire. After the tire has been dismounted.. it should be thoroughly INSPECTED. During this inspection, check the inside surface carefully, to locate the puncture and determine the nature and extent of the damage.

The Rubber Manufacturer's of America list two requirements for correctly repairing a puncture- the repair MUST fill the injury to the tire and the repair MUST soundly patch the inner liner. Various products are available for repairing the puncture to the tire. including plugs and liquid sealants.

The basic procedures for repairing a tubeless tire are as follows:

Select a patch of sufficient size to extend well beyond the damaged area, so it will adhere properly and withstand the heat and mechanical stress of the tire.

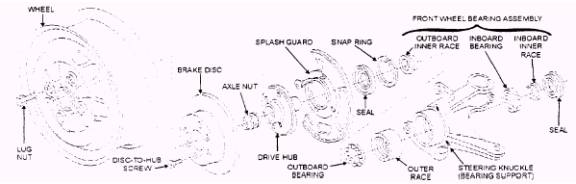

Figure 8-40.- Disassembled view of a driving wheel bearing and hub assembly.

Scuff (roughen) the area that the patch will cover, so it will adhere tightly.

Apply the proper cement (adhesive), following the directions in the tire repair kit.

Remove the covering from the adhesive side of the patch and carefully place it on the inner liner.

Using a tool, called a sticher, roll it across the patch to bond the patch tightly to the inner liner.

A few basic safety rules for repairing a tubeless tire are as follows:

Do NOT attempt to repair a puncture by plugging the tire from the outside. ALWAYS dismount the tire and patch the inner liner.

Do NOT attempt to repair sidewalls or tires with punctures larger than a 1/ 2 inch.

Reduce the air pressure to at least 15-psi, when removing an object from the tire.

Broken strands in a steel belted tire can indicate more serious damage than initially suspected. Replace the tire.

Follow the procedures given in the tire repair kit.