|

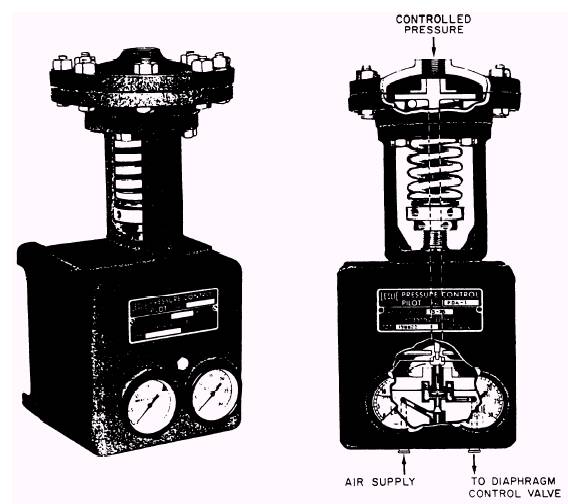

Air-Pilot-Operated

Diaphragm Control Valves These

valves are used extensively on naval ships. The valves and their control pilots

are available in several designs to meet different requirements. They may be

used as unloading valves to reduce pressure or to provide continuous regulation

of pressure and temperature. They may also be used for the control of liquid

levels. The air-operated control pilot may be either direct acting or reverse

acting. A direct-acting pilot is shown in figure 13-30. In this type of pilot,

the controlled pressure-that is, the pres-sure from the discharge side of the

diaphragm control valve-acts on top of a diaphragm in the control pilot. This

pressure is balanced by the pressure exerted by the pilot adjust-ing spring.

When the controlled pressure in-creases and overcomes the pressure exerted by

the pilot adjusting spring, the pilot valve stem is forced downward. This action

opens the pilot valve to increase the amount of operating air pressure going

from the pilot

to

the diaphragm control valve. A reverse-acting pilot has a lever that reverses

the pilot action. In a reverse-acting pilot, therefore, an increase in

controlled pressure produces a decrease in operating air pressure. In the

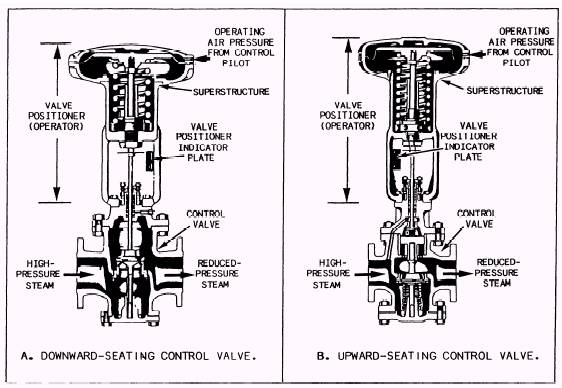

diaphragm control valve, operating air from the pilot acts on a diaphragm

contained in the superstructure of the valve operator or posi-tioner. (See fig.

13-31.) It is direct-acting in some valves and reverse-acting in others. If the

valve operator is direct-acting, the operating air pressure from the control

pilot is applied to the TOP of the valve diaphragm. When the valve operator is

reverse-acting, the operating air pressure from the pilot is applied to the

UNDERSIDE of the valve diaphragm.

View

A in figure 13-31 shows a very simple type of direct-acting diaphragm control

valve. The operating air pressure from the control pilot is applied to the top

of the valve diaphragm. The valve in the figure is a downward-seating valve.

Therefore, any increase in operating air pressure

Figure 13-30.-Air-operated

control pilot.

Figure 13-31.-Diaphragm

control valves.

pushes

the valve stem downward. This tends to close the valve.

Now

look at view B. This is also a direct-acting valve. The operating air pressure

from the con-trol pilot is applied to the top of the valve diaphragm. But the

valve shown in view B is more complicated than the one shown in view A. The

valve shown in view B is an upward-seating valve rather than a downward-seating

valve. Therefore, any increase in operating air pressure from the control pilot

tends to OPEN this valve rather than to close it.

As we

have seen, the air-operated control pilot and the positioner of the diaphragm

control valve may be either direct-acting or reverse-acting. In addition, the

diaphragm control valve may be either upward-seating or downward-seating. These

factors, as well as the purpose of the installation, determine how the

diaphragm control valve and its air-operated control pilot are installed in

rela-tion to each other.

To

see how these factors are related, lets con-sider an installation; a diaphragm

control valve and its air-operated control pilot are used to supply reduced

steam pressure. Figure 13-32 shows one arrangement that we might use. We will

assume that the service requirements indicate the need for a direct-acting,

upward-seating, diaphragm control valve. Can you figure out which kind of a

control pilot-direct-acting or reverse-acting- should be used in this

installation?

Figure 13-32 .-Arrangement of control pilot and

diaphragm control valve for supplying reduced steam pressure.

Lets

try it first with a direct-acting control pilot. The controlled pressure

(discharge pressure from the diaphragm control valve) increases. When that

happens, increased pressure is applied to the diaphragm of the direct-acting

control pilot. The valve stem is pushed downward and the valve in the control

pilot is opened. This sends an in-creased amount of operating air pressure from

the control pilot to the top of the diaphragm control valve. The increased

operating air pressure acting on the diaphragm of the valve pushes the stem

downward. Since this is an upward-seating valve, this action OPENS the

diaphragm control valve still wider. Obviously, this wont work-for this

application, an INCREASE in controlled pressure must result in a DECREASE in

operating air pressure. Therefore, we made a mistake in choos-ing the

direct-acting control pilot. For this particular pressure-reducing application,

we should choose a REVERSE-ACTING control pilot.

You

will probably not need to decide which type of control pilot and diaphragm

control valve are needed in any particular installation. But you must know how

and why they are selected so that you will not make mistakes in repairing or

replac-ing these units.

|