|

Underhung Leads Underhung leads are composed of exactly the same sections used for swinging leads. Underhung leads are bolted together on the ground, as described for swinging leads, and connected to the boom tip through the use of lead adapters (fig. 12-52). The boom tip sheaves are used to accommodate the pile and the pile-driving hammer. All underhung leads have a standard bolt hole layout for bolting the lead adapters to the leads; however, the dimensions of the boom tip end of the adapters vary according to the make and model of the crane. After the adapters are connected to the boom, the boom is raised to bring the leads to a vertical position (fig. 12-53). Long lead sections may require the use of support equipment to raise the leads to a vertical position. NOTE: Check the adapter bolts for tightness at the beginning of each pile-driving shift. Adapter plates are mounted to the boom butt or crane cab and on the bottom lead section for connection of a fore-and-aft bottom brace, commonly known as a catwalk. The catwalk can be extended or telescoped to various lengths. It can be set to hold the leads vertical for driving bearing piles or to hold them at an angle for driving batter piles. In use, an underhung lead is held by the boom at a fixed radius (fig. 12-54).

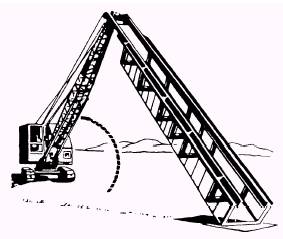

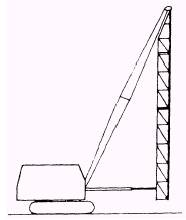

Figure 12-53.-Underhung leads being raised by the boom.

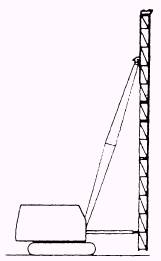

Figure 12-54.-Underhung leads. ADVANTAGES.- Some advantages of using underhung leads over other types of leads areas follows: 1. They are lighter and generally less expensive than the extended four-way type of lead. 2. They require only a two-hoist drum crane. 3. They provide accuracy in positioning leads in vertical and fore-and-aft batter positions. 4. They provide precise control of the leads during positioning operation. 5. They reduce rigging time in setting up and breaking down. 6. They use boom tip sheaves. DISADVANTAGES.- Some disadvantages of using underhung leads are as follows: 1. They cannot be used for side-to-side batter driving. 2. The length of pile is limited by boom length, since this type of lead cannot be extended above the boom tip. 3. When long leads require the use of long boom lengths, the working radius that results may be excessive for the capacity of the crane. 4. They do not allow the use of a boom shorter than the lead. Extended Four-Way Leads Extended four-way leads use the same intermediate lead sections as swinging and underhung leads. In place of a 15-foot tapered section, an extended lead uses a 30-foot slide section with a sheave head assembly. A universal sliding boom tip connector, slipped into the 30-foot slide section, connects to the boom tip (fig. 12-55). The sliding boom tip connector swivels, allowing for driving batter piles in all directions. The boom is lowered over the leads when connecting the boom tip to the sliding boom connector. The connector is bolted into the 30-foot slide section at the location dictated by the amount of lead extension desired above the boom tip. NOTE: Extension of the lead over the boom tip must not exceed one third of the total lead length or up to 25 feet maximum.

Figure 12-55.-Sliding boom tip connector.

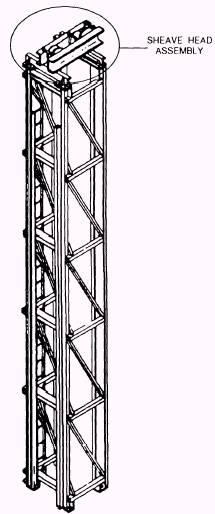

Figure 12-56.-Extended four-way lead. The boom is raised to raise the leads. The type of catwalk used is a hydraulic or mechanical parallelogram bottom brace. This type of brace allows for a fixed radius or side-to-side batter by swinging the linked parallelogram in the desired position. The parallelogram allows for pile driving in all directions at the bottom. Figure 12-56 shows an extended four-way lead. The boom point sheaves are not used to accommodate the pile-driving hammer and the piles. The extended four-way leads are equipped with a special sheave head assembly (fig. 12-57) that the two-hoist drum wire rope reeves through to support the pile-driving hammer and the piles. ADVANTAGES.- Some advantages of using an extended four-way lead are as follows:

Figure 12-57.-Sheave head assembly. 1. It requires only a two-hoist drum crane. 2. It provides accuracy in locating leads in all batter positions. 3. It provides rigid control of the leads during positioning operation. 4. It allows batter angles to be set and accurately maintained. 5. It allows for the use of short boom angles that increases the crane capacity. 6. The boom can be lowered and leads folded under for short hauls over the road when a crane with adequate capacity is used This operation depends on the length of the lead and boom and the configuration of the crane. DISADVANTAGES.- Some disadvantages of using an extended four-way lead are as follows: 1. It is the heaviest and most expensive of the three basic lead types. 2. It is more troublesome to assemble. Spud Leads A spud lead is a steel wide flange or H-beam used in place of pile-driving hammer leads. The pile-driving hammer rides on the flange of the beam through spud clips bolted to one side of the pile-driving hammer (fig.

12-58). Depending on the design of the spud lead, the spud can be used as a swinging and underhung lead or equipped with a sheave head assembly as an extended four-way lead An advantage of this type of lead is that it bears the whole bottom of the pile cap to the piling especially when sheetpiling is being driven (fig. 12-59).

|