|

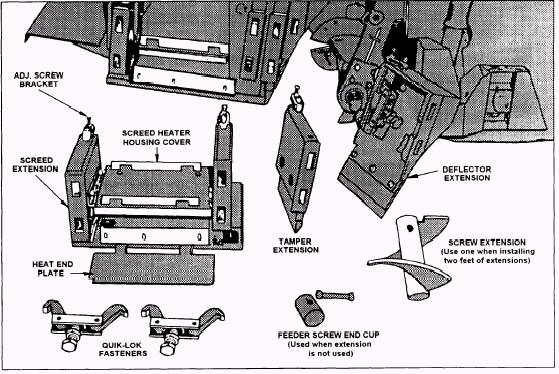

SCREED HEATERS.- The screed is equipped with heaters, used to heat the screed plate at the start of each new paving operation. The heaters are not used to heat the mix during the paving operation. If the screed is not initially heated, the mix will tear and the texture will look open and coarse, as it would if the mix were too cold. There are times when the paver operator allows the mix to heat the screed plate. This practice almost always results in a section of unsatisfactory pavement being laid while the screed is being heated. SCREED ACCESSORIES.- Three types of commonly used screed accessories are screed extensions, cutoff shoes, and bevel end plates. Screed Extensions.- Screed extensions (fig. 16-46) are attachments that widen the screed, allowing the paver to place a wider-than-normal mat. On some

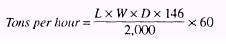

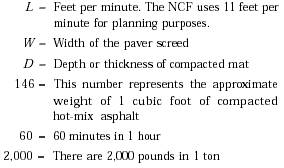

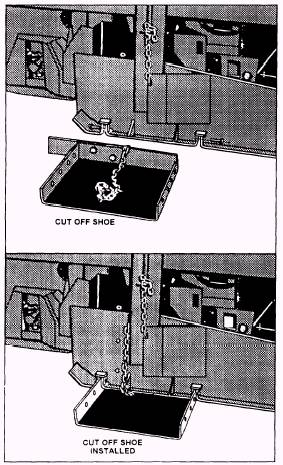

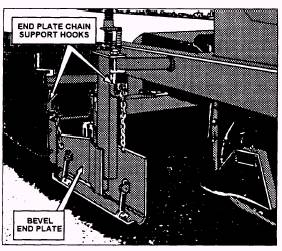

Figure 16-46.-Screed extension accessories. models, screed extensions make it possible to pave widths up to 24 feet in a single pass. Cutoff Shoes. - Cutoff shoes (fig. 16-47) have the opposite function of screed extensions. They are metal plates inserted into the screed to reduce the width of the mat being placed. Bevel End Plates.- Bevel end plates (fig. 16-48) are used to bevel the edge of the mat. On some models, the shoes can be set at any one of three positions: vertical, 30 degrees, or 45 degrees. Tons Per Hour The equation, used to compute the amount of asphalt that can be layed with a paver per hour, is as follows:

Where

Example: The required tonnage of hot-mix asphalt for a project is 800 tons. The screed of the paver is set at 10 feet, and the depth of asphalt is 2 inches. Estimate the amount of asphalt that can be laid per hour.

By planning and estimating the amount of hot-mix asphalt that can be laid per hour, you are able to tell the asphalt plant exactly how much hot-mix asphalt is required to be delivered per hour or per day. MAINTENANCE As an Equipment Operator, it is your responsibility

Figure 16-47.-Cutoff shoes.

Figure 16-48.-Bevel end plates. to coordinate the proper operation, care, use, adjusting, cleaning, preservation, and lubrication of paving and support equipment. This includes daily inspections and adjustments, required for good operation. Malfunctions in equipment, which go beyond those operating adjustments performed by the EO, should be referred to the field mechanic for corrective action. This does not release you from working with the field mechanic unless you are directed otherwise.

|