|

PRIMARY LINT TRAPS

The primary lint trap is located in the front of the machine

inside the lower lint trapdoor. Figure 5-27 illustrates a laundryman cleaning the

lint trap and lower casing. Cleaning the primary lint trap and lower casing should be done once every 2 hours. Proper cleaning of the lint trap eliminates airflow restrictions which increase the time for drying each load and create possible fire hazards. SECONDARY LINT TRAPS

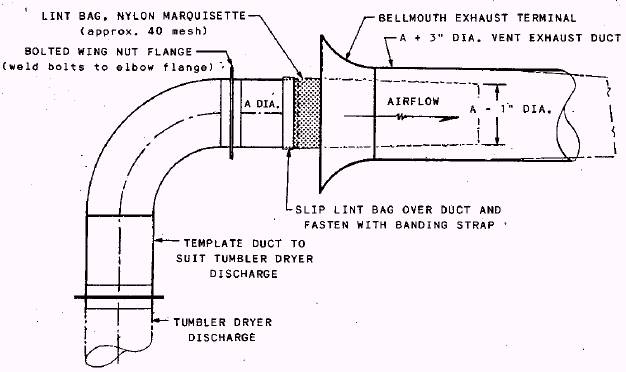

Secondary lint traps help to cut down the buildup of lint in ducting. Air that has gone through the primary lint trap and left the dryer still may have lint in it. This lint and debris build up in the ducting blocking airflow. Ducts that have long runs and elbows attract lint that gets stuck and builds up creating back pressure and a possible fire hazard. Inspection and cleaning of these vents and ducts should be done monthly. Secondary lint traps can be installed by procuring dryer lint trap bags and installing them as indicated in figure 5-28. Lint bags are available

Figure 5-27.-Laundryman cleaning the primary lint trap.

Figure 5-28.-Secondary lint trap installation. through sources contained in the Ship's Store Contract Bulletin. These bags are easy to install and remove and should be cleaned once every 4 hours. STEAM COILS

Steam coils are located at the top of the dryer. The configuration of steam coils as heat ex-changers makes them collectors of lint and dirt, which slows down the transfer of heat and reduces airflow. Steam coils should be examined daily for the presence of lint; any lint present must be removed.

|