|

OPERATION OF THE FLATWORK IRONER Before you start and operate the flatwork ironer, make sure you fully understand the use of each control and the equipment safety precautions. The compression roll should be disengaged (top position) and flatwork ready to be fed into the machine. Follow these steps: 1. Start ironer by pressing the green button.

2. Set to the lowest speed by adjusting the speed control handle.

NOTE: NEVER change the speed of the ironer when the ironer is on or you may damage the variable speed mechanism. 3. Open the steam supply valve slowly. Open the valve one-half a turn at first and gradually allow steam to enter the cylinder. Continue to open the valve slowly until opened all the way. The steam pressure for the ironer should be about 100 psi. It normally takes about 30 minutes to fully heat the cylinder. 4. Engage the compression roll and wax the ironer (see waxing the ironer).

5. Start feeding the flatwork. You may increase speed to meet your particular need. During normal operation there are two locations in which the ironer maybe stopped, the red finger safety guard and red emergency stop button.

6. To stop the ironer at the end of your work, close the steam supply, raise the compression roll, and allow the machine to run without steam for 20 to 30 minutes. This procedure allows all

components to properly cool before the power is shut off. This cool-down procedure also prevents damage to return ribbons and protects the compression roll padding from being flattened. FEEDING THE FLATWORK IRONER

The flatwork ironer was designed to finish all cotton or blended flatwork such as tablecloths, napkins, towels, and linen. It is not designed to process nylon or rubberized fabrics. Do not try to process these items as it may result in fire or damage to ribbons or cylinder surface. When leaving the ironer for more than 5 minutes, always raise the compression roll. To help ease feeding, you should shake a quantity of work out and lay it over the edge of the laundry basket or on a table within easy reach.

Check on the amount of dampness in the pieces before feeding. The piece should come out

of the ironer dry, and to accomplish this, some adjustment of the extracting time may be necessary. If the pieces are not extracted long enough they will come out of the ironer still damp; and if extracted too long they will come out with a rough, dry appearance. Do not let flatwork sit around in the laundry baskets after it is removed from the extractor. Iron flatwork immediately while it is at the proper stage of dampness, or cover it with plastic or other material to retain a proper amount of moisture. Feed flatwork into the ironer WRONG SIDE UP, so that the smooth or "right" side comes into contact with the cylinder. This gives a smooth finish to the outside of the flatwork. Fold the smooth side out as the work comes from the machine. Large Items

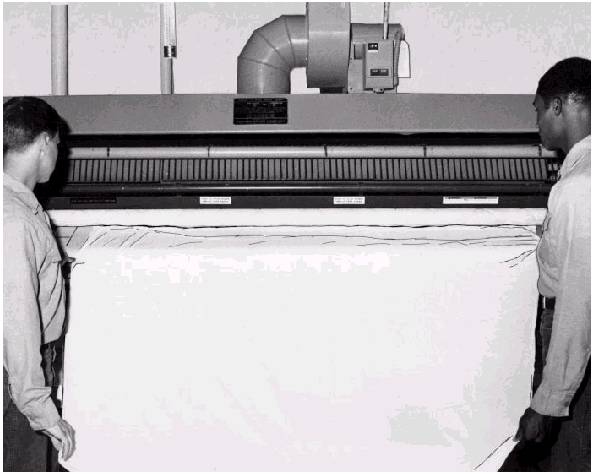

Two persons should feed large items as shown in figure 5-31. To start the piece through the ironer, each person grasps a top corner with the hand nearest the ironer, stretching the forward edge between them so that it enters the machine straight and smooth. Each person uses the other hand to straighten the front edge as it enters the ironer. After the feed roll ribbons pick up the spread, they use both hands to hold the spread firm and straight as it passes through the ironer. As the spread comes out, the personnel take it by the edges again and fold it.

Small Items

When you feed small articles into the flatwork ironer, use the entire length of the cylinder, If you continually feed small items into the ironer at one or two spots, the padding on the pressure rolls wears more at these points and your work comes out unsatisfactory. The only way to correct this difficulty is to repad the rolls.

CARE AND MAINTENANCE

Maintenance of the flatwork ironer is the responsibility of engineering personnel. ONLY trained maintenance personnel should do any work on the ironer. Instructions for changing

Figure 5-31.-Laundry personnel using the flatwork ironer. ribbons, aprons, friction material on ribbon drive rolls, pads, and covers are contained in the manufacturer's technical manual. Laundry personnel should do this maintenance ONLY after being properly trained in the correct procedures for performing this work. Waxing the Ironer

To produce a smooth finish on flatwork, prolong ribbon life, and prevent linen from sticking to the heated cylinder, laundry personnel need to wax the ironer each morning or after every 6 to 8 hours of use. You should use the wax recommended by the manufacturer. Cut a strip of cloth about 3 feet wide and as long as the cylinder. Sprinkle half of the strip evenly with wax (paraffin) and fold the other half over it. Hold the cloth tight and feed the closed or folded end into the ironer. Run the paraffined cloth through the ironer several times. Use caution when doing this as the wax may become very hot. Also, be careful not to overwax as this causes the return ribbon and drive material to deteriorate. This cloth may be reused as long as the wax lasts. Never sprinkle wax directly onto the ironer. Ironer Ribbons

Ironer ribbons need to be replaced when they become worn, discolored, or torn. After they have been replaced by trained maintenance personnel, laundry personnel should thoroughly wax the ironer as this aids the newer ribbons in their initial action against the heated rolls. Friction Material on Return Ribbon Drive Roll The return ribbon drive roll drives the ironer return ribbons. This return ribbon drive roll is located at the front of the ironer underneath the white canvas feed ribbons. For the ironer return ribbons to be driven properly, the ribbon drive roll must be properly covered with friction material. Special 6-inch-wide friction material wound around the drive roll is used for this purpose. When this material becomes smooth or if it should become worn off the roll, it must be replaced with new material. If this material is not replaced, the ironer return ribbons will not be driven at the proper speed and wrinkling and other problems can result. Return ribbons normally run faster than the heated roll and the padded compression roll. If linens should have a tendency to jam and wrinkle while under the return ribbons, that is usually an indication that the ribbons are not running at the proper speed and the friction material may need replacement. You should contact maintenance personnel to check and replace this friction material if necessary. Changing Combination Pads and Covers When the padding on the ironer pressure rolls becomes scorched, burned, or when resiliency is lost they should be changed. It is very dangerous to install new padding to the ironer and must be done with a great deal of care because your hands come close to moving rolls. Only experienced maintenance personnel should install the padding.

After the padding is installed, the operator should make sure all safety guards are reinstalled by maintenance personnel and work properly. You should also run a wax cloth through the ironer two or three times.

If the padding at one end of an ironer is slightly larger in size than the other end, pass some heavy bath towels or other thick work through at that end. This should compress the padding sufficiently so that the padding is the same diameter across the entire width of the roll. There should be a minimum of pressure on the padding, This allows maximum padding life. Do not try to maximize pressure that is put on the padding. The ironer will not dry better because of extra pressure. It simply wears out the padding faster,

As the padding gets older, it compresses slightly.

|