TIMING AND ADJUSTMENTS

The 31-15 sewing machine is the simplest sewing machine in the parachute loft. As with all oscillating-shuttle machines, the main timing point is the needlebar. Once the needlebar is properly set, only minor adjustments are necessary to have a smooth-running sewing machine. Remember you should always refer to the troubleshooting chart before making any adjustment.

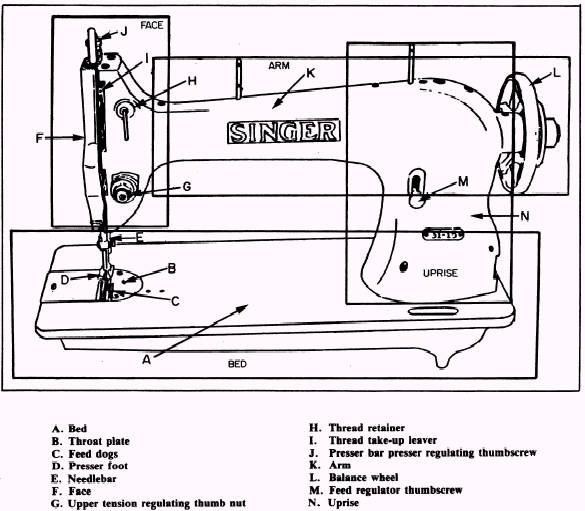

Figure 4-13.\Front view of model 31-15 sewing machine.

Timing the Needle with the Shuttle

When the needle and shuttle are correctly timed,

the point of the shuttle on its forward stroke must pass across the center of the diameter of the needle

at a point one-sixteenth of an inch above the eye of the needle when the needle is on its upstroke. To time the machine so the needle and

shuttle operate properly, you must proceed as follows: Be sure that the needle is a class 16

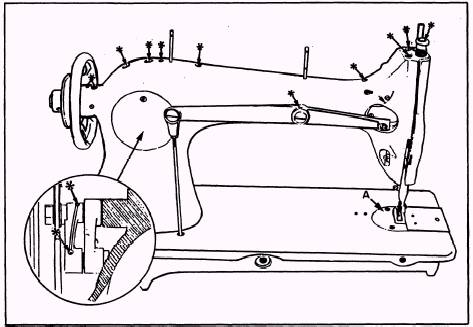

Figure 4-14.\Rear view of oiling points on model 31-15 sewing machine.

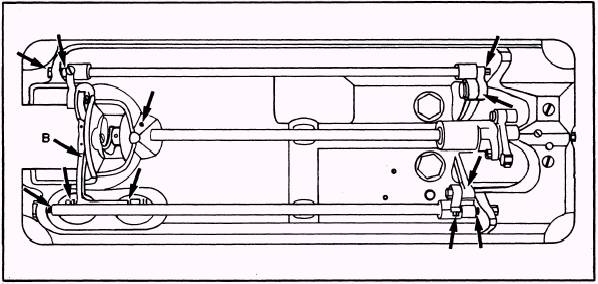

Figure 4-15.\Bottom view of oiling points on model 31-15 sewing machine.

and a variety 87 (16 x 87). Place the needle into the needlebar as far as it will go. Be sure the long thread groove faces the left and the eye of the needle is in line with the shuttle point. Remove the faceplate and loosen the needlebar connecting stud pinch screw (figure 4-16 [A]). Turn the balance wheel toward the operator until the needlebar is on its upstroke and the point of the shuttle is in the center of the eye of the needle. Adjust the needlebar so that the eye of the needle is one-sixteenth of an inch below the shuttle point (figure 4-16 [B]). Now retighten the needlebar connecting stud pinch screw (figure 4-16 [A]).

NOTE: The main timing point for the 31-15 sewing machine is the needlebar.