|

ENGINEERING

OPERATIONAL CASUALTY CONTROL (EOCC).The casualty control portion of EOSS

contains information relative to the recognition of casualty symptoms and their

probable causes and effects. In

addition, it contains information on preventive action to be taken to preclude

a casualty and on procedures for controlling single and multiple source

casualties.

Casualty

prevention must be the concern of everyone on board. Proper training of all

personnel must provide for adequate knowledge and experience in effective

casualty prevention. The EOCC manual contains efficient, technically correct

casualty control and prevention procedures which relate to all phases of an

engineering plant. The EOCC documents elaborate on possible casualties caused

by error, material failure, and battle. The EOCC manual describes tried and

proven methods for the control of a casualty and prevention of further damage

to the component, the system, or the engineering plant concerned.

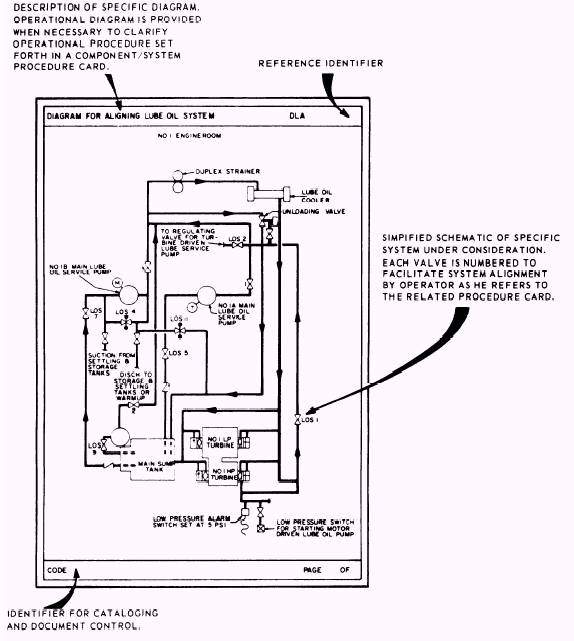

Figure 2-23.Sample

Component/System Alignment Diagram.

The

EOCC manuals are available to the personnel in their own machinery space so that they can be used as a

means of self-indoctrination for newly assigned personnel and as an instrument

with which to improve casualty control procedure techniques for all

watchstanders. The manual contains the documentation required to effectively

assist engineering personnel in developing and maintaining maximum proficiency

in controlling casualties to the ships propulsion plant. Proficiency in EOCC

procedures is maintained through a well-administered training program.

Primary

training concentrates on controlling single-source casualtiesthose which may

be attributed to the failure or malfunction of a single component or the

failure of piping at a specific point in a system. Advanced training

concentrates on controlling multiple casualties or on conducting a battle

problem. An effective and well-administered EOOW training program must contain,

as a minimum, the following elements: Recognition of the symptoms.

Probable

causes.

Probable

effects.

Preventive

actions that may be taken to reduce, eliminate, or control casualties.

An

EOSS package is not intended to be forgot-ten once it is developed and

installed aboard a ship. It offers many advantages to the ships operational

readiness capabilities, providing detailed step-by-step sequencing of events

for all phases of the engineering-plant operation. Its procedures are tailored

to each specific ship and are prepared for each level of management and

operation. Because it is work-studied and system-oriented, the EOSS provides

the basic information for the optimum utilization of equipment and systems by

specifying correct procedures tailored for a specific plant configuration.

The

EOSS is not intended to eliminate the need for skilled plant operators. No

program or system can achieve such a goal. The EOSS is a tool for better

utilization of manpower and skills available. Although the EOSS is an excellent

tool for shipboard training of personnel, it is primarily a working system for

scheduling, controlling, and directing plant operations and casualty-control

procedures.

|