|

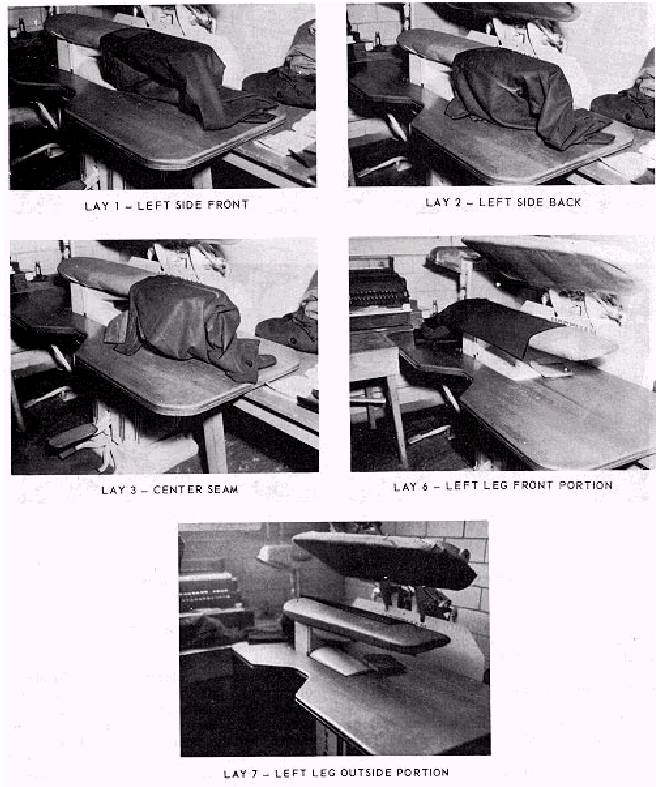

Enlisted Men's Trousers Figure 6-9 shows the sequence of lays for pressing enlisted men's trousers. The procedure is the same for both blues and whites.

Turn the trousers inside out for the entire pressing operation. Place the left front of the trousers on the small end of the buck, smooth out the flap, and then apply steam and vacuum dry. See lay No. 1. In lay No. 2, the left side back is placed on the small end of the buck, even with the side crease. Smooth out all wrinkles, apply steam freely, and vacuum dry.

In making lay No. 3, draw the trouser top over the small end of the buck so that the end of the buck fits well into the seat of the trousers and the back seam is directly in the center of the buck. Apply steam and light pressure and vacuum dry. In making lay No. 4 and lay No. 5, continue on around the trouser top. These lays are not shown as they correspond closely to lay Nos. 2 and 1. In lay No. 6, place the front portion of the left leg on the buck, crotch at the large end. With

the seam facing up, running parallel to inside crease, apply light pressure and vacuum dry. Lay the left leg, as shown in lay No. 7, at the rear of the buck, so the outside crease is in the center of the buck in line with the bottom of flap, to avoid crushing buttons, Apply steam fully to take out fullness of knee and vacuum dry. Lay No. 8 (right leg, front portion) and lay No. 9 (right leg, outside crease) are substantially the same as lay Nos. 7 and 6. Enlisted Men's Jumpers

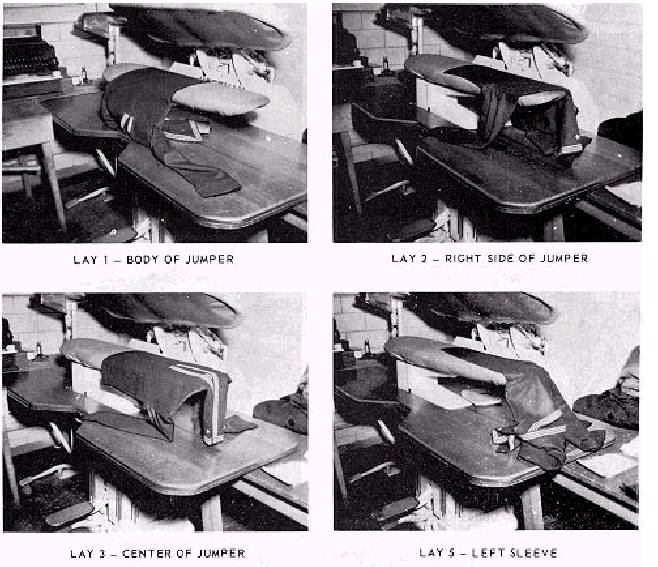

Figures 6-10 and 6-11 give the sequence of lays for pressing enlisted men's jumpers. The procedure is the same for both blues and whites. Turn the jumper inside out for the entire pressing operation. Place the body of the jumper on the center of the buck. Apply light pressure, steam, and vacuum dry. See lay No. 1. Place the right side of the jumper on the small end of the buck (lay No. 2), extending from shoulder to bottom. Insert your right hand into the shoulder seam, smoothing out wrinkles. Apply steam and vacuum dry. In lay No. 3, place the center of the jumper on the small end of the buck about 6 inches above the

vee. Apply light pressure, steam, and vacuum dry. Lay No. 4 is pressed in the same manner as lay No. 2. Place the sleeve in the center of the small end of the buck as shown in lay No. 5, making sure creases correspond with the body crease and the shoulder crease. Smooth out all the wrinkles by applying light pressure to avoid crushing buttons on cuffs. Lay No. 6 is pressed in the same manner as lay No. 5. In lay No. 7, place the collar in the center of the buck and fold the sides to meet in the center

as shown in lay No. 7. Apply plenty of pressure. Then fold the collar again so that the two outside creases are matched evenly. Place on the center of the buck and apply plenty of pressure. See lay

No. 8. In lay No. 9, fold the jumper in the center so that both sides of the jumper match. Place the center fold on the buck, apply light pressure, steam freely, and vacuum dry. STEAM AIR FINISHER

When available, use the steam air finisher to finish such items as coats, overcoats, peacoats,

and foul weather jackets. There are three styles of air finishers installed aboard Navy vessels. The

Figure 6-9.-Lays for pressing enlisted men's trousers.

Figure 6- 10.-Lays 1, 2, 3, and 5 for pressing enlisted men's jumpers. Ajax model is illustrated in figure 6-12. These air finishers make jobs in large dry-cleaning plants quicker and more efficient.

|

|