|

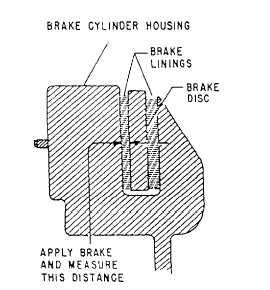

Brake Wear Check Lining wear may be checked by two methods. Before

checking the brakes on any aircraft, always refer to

the applicable MIM and use the method recommended

by the aircraft manufacturer.

WEAR CHECK METHOD (NO. 1). Have

a person in the cockpit apply the

brake, and with the brake applied,

measure the distance between the face of the brake

disc and the brake housing, as shown in figure 12-37.

If this distance has progressed to the maximum specified

measurement given in the MIM, the brake should

be removed and disassembled, and the lining pucks

inspected for wear.

NOTE: Linings can be

measured only by removing and

disassembling the brake. If any puck

has worn to a thickness of less than one-sixteenth

inch, the entire set must be replaced.

NEVER MIX NEW AND USED LININGS.

WEAR CHECK METHOD (NO. 2). -In

using this method, have a person in

the cockpit apply the brake. With

the brake applied, check the position of the automatic

adjusting pins (fig. 12-38). If any adjusting pin

recedes inside the adjusting pin nut (one-sixteenth to

three-eighth inch, the exact amount depending on the brake

model), the brake must be removed and disassembled,

and the lining thickness checked. If any

Figure 12-37.-Checking lining wear (method No. 1).

lining is worn to a thickness of one-sixteenth inch or less,

the entire set of linings must be replaced. Figure 12-38

illustrates the normal position of the automatic adjusting

pin (protruding out of the adjusting pin nut).

|

|