|

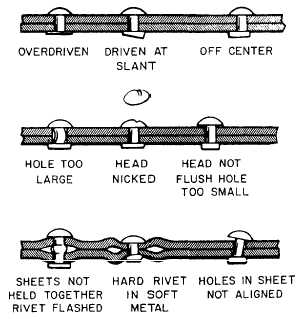

Rivet Removal Rivets must be removed and replaced if they show

even the slightest deformity or lack of alignment.

Reasons for replacing rivets are as

Figure 13-46.-Rivet dimensions

before and after bucking.

follows: rivet marred by bucking bar or

rivet set; rivet driven at slant or

shank bent over; rivet too short, causing

the head to be shallow; rivet pancaked too flat from

overdriving; sheets spread apart and rivet flashed

between the sheets; two rivet heads not in alignment;

and head of countersunk rivet not flush with

outside surface or driven below surface. Examples

of these incorrectly driven rivets are shown in

figure 13-47.

When you are removing rivets, be careful not to enlarge

the rivet hole. This will require you to use a larger

size rivet for replacement. To remove a rivet, file

a flat surface on the manufactured head. It is always

preferable to work on the manufactured head rather

than on the one that is bucked, since the former will

always be more symmetrical about the shank. Indent

the center of the filed surface with a center punch,

and use a drill of slightly less than shank diameter

to drill through the rivet head. Remove the drill

and, with the other rivet end supported, pry or lightly

tap off the head with a drift punch. If the shank

is too tight after the removal of the head, the shank

should be drilled out. However, if the sheet is

firmly supported from the opposite side, the

Figure 13-47.-Incorrectly driven

rivets.

shank may be punched out with a drift punch. See figure

13-48.

The removal of flush rivets requires slightly more skill.

If the formed head on the interior is accessible and

has been formed over heavy material, such as an extruded

member, the formed head can be drilled through

and sheared off. If the material is thin, it may be

necessary to drill completely through the shank of the

rivet, and then cut the formed head with diagonal-cutting

pliers. The remainder of the rivet may

then be drifted out from the inside.

|