|

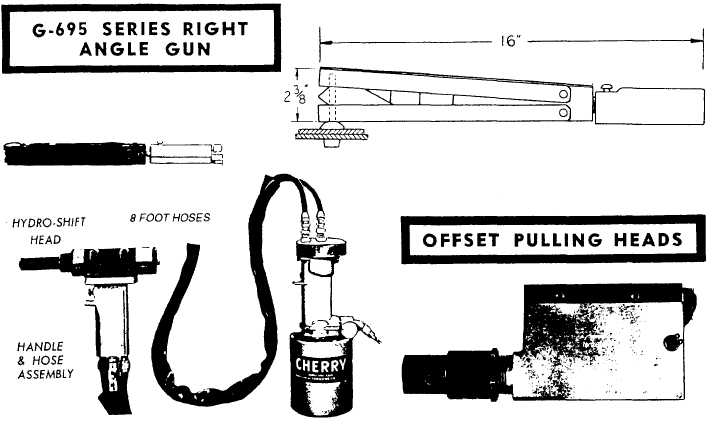

The equipment used for the installation of cherrylock

rivets is similar to the buck rivet. See figure

13-50. The operation and adjustment of the pulling

heads are preset during manufacture. If further

adjustment should become necessary, the procedures

provided with the head or in the maintenance

manual should be followed. To install a pulling

head of the H615A series, engage the threaded portion

of the pulling head sleeve cap and drawbolt to the

gun head and drawbolt. Then tighten the screws and

the jam nut. The pulling head of an H640A series is

installed by engaging the internal threads of the head

piston rod. Then align the holes in the pulling head

with those on the gun adapter, and tighten one setscrew. To install the nose assembly used on

the hydro-shift head equipped gun

(fig. 13-5 1), you should proceed as

follows:

1. Remove the retainer nut from the hydro-shift head.

2. Place the jaw assembly in the collet (with the spring

protruding).

3. Screw the internal threads of the collet onto the

drawbolt of the hydro-shift head.

4. Slip the sleeve assembly over the collet.

5. Place the retainer nut over the sleeve assembly and

tighten it onto the gun.

Cherrylock rivets require a separate pulling head for

each diameter and head style. Each series of gun also

uses a different set of pulling heads. Refer to the appropriate

operating manual for the proper head for each

rivet and gun.

There are also special use cherrylock pulling heads

(fig. 13-52) for use in areas where access is limited.

Figure 13-52.-Specia1 use heads.

Since huck and cherrylock rivets are similar, the installation,

inspection, and removal procedures are basicaIly

the same.

|