|

Ejection Control Assembly Check-out

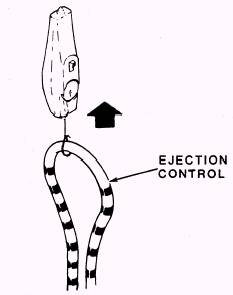

Checking the ejection control assembly is a four part procedure. The first part of the procedures shown in figure 6-47.

1. Install the initiation pull-test tool set. Ensure the ejection initiator pull-test tools are not preloaded. Position the safe/ arm control to the full UP position. Attach a push-pull gauge to the ejection control assembly. Pull upward and record the breakout force. The breakout force should be 15 to 25 pounds.

2. Lower the safe/ arm control to the full DOWN position. Continue pulling upward on the ejection control assembly until the pull-test tools extend to the relaxed position. The force required to accomplish this task should be 15 to 40 pounds. You should ensure that the ejection control assembly does not separate from the seat. You should also observe the initiation rotors rotating past the safety plunger.

3. Stow the ejection control assembly while manually returning the initiation subsystem rotors to the ARMED position. Then install the initiation pull-test tool to the upper connect and disconnect sear. At this point you can simulate automatic seat/ man separation by rotating the emergency release handle to the full UP position. Notice that the upper connect and disconnect sear moves down, and the pull-test tool extends to the relaxed position. Check to see that the T-bar is

Figure 6-47.- Ejection control assembly check-out.

in the full UP position, and that it is blocking the initiation rotors.

4. Raise the safe/ arm control to the UP and LOCKED position. Lower the emergency release handle to the DOWN and LOCKED position. Remove the initiation pull-test tool set.

|