Wheel Balancing

Improper wheel balance is the most common cause of tire vibration. Often a tire will appear to be round and true when rotated slowly. However, when one side is heavier than the other. centrifugal force tries to throw the heavy area outward during operation. To obtain maximum tire wear and a comfortable ride, you should balance the wheels. The two types of tire imbalance are as follows: DYNAMIC IMBALANCE (fig. 8-42) lies on either or both sides of the center line of the tire, which causes the tire to vibrate up and down (wheel hop) and from side to side (wheel shimmy). To be in dynamic balance, the top-to-bottom weight and the side-to-side weight must all be equal.

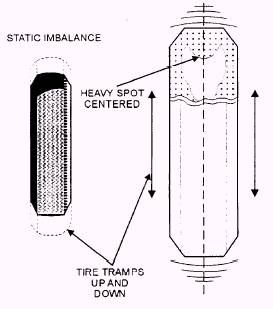

STATIC IMBALANCE (fig. 8-43), also called wheel tramp or hop, lies in the plane of wheel rotation, which causes the tire to vibrate up and down. For a wheel and tire assembly to be in static balance, the weight must be evenly distributed around the axis of rotation.

To static balance a wheel and tire assembly, add wheel weights opposite the heavy area of the wheel. If a large amount of weight is needed, add half to the outside and the other half to the inside of the wheel. This will keep the dynamic balance of the tire. However. when dynamically balancing a wheel and

Figure 8-43.- Static imbalance.

tire assembly, the weights must be added exactly where needed (fig. 8-44).

A wheel-balancing machine is used to determine which part of a wheel assembly is heavy. The three types of balancing machines are as follows:

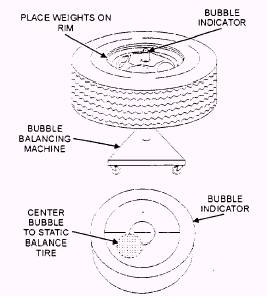

BUBBLE BALANCER (fig. 8-45) is the most common type of balancer used by the NCF. This type of balancer will ONLY statically balance a wheel

Figure 8-44.- How weights should be placed when balancing tires.

Figure 8-45.- Bubble balancer.

assembly. The wheel assembly must be removed from the vehicle and placed on the balancer. An indicating bubble on the machine is used to locate the heavy area of the assembly. Wheel weights are added to the assembly until the bubble CENTERS on the crosshairs of the machine.

OFF-THE-VEHICLE BALANCER (spin balancer) can statically and dynamically balance a wheel assembly. The wheel assembly is removed from the vehicle and mounted on the balancer. The assembly is then spun at a high rate of speed. The machine detects any vibration of the assembly and indicates where the wheel weights are to be added. After the weights are added to the assembly, spin the assembly to again check for vibration.

ON-THE-VEHICLE BALANCER (spin balancer) (fig. 8-46) is also used to balance a tire statically and dynamically. An electric motor is used to spin the wheel assembly and either a electronic pick-up unit or hand-operated device is used to determine the location for the wheel weights. An on-the-vehicle type balancer is desirable because it can balance not only the wheel assembly, but the wheel cover, brake disc or drum, and lug nuts. Everything is rotated as a unit.