|

PREPARING A MILSTRIP REQUISITION

LEARNING OBJECTIVE : Recognize MILSTRIP requisition procedures and how

they are used for material receipt, custody,

and stowage.

MILSTRIP uses coded data for processing

requisitions with automatic data processing

equipment. No matter what type of requisitioning

document you use, use extreme care in

selecting and entering the coded data

elements. These codes apply to all

levels of supply. Although they are too numerous

for all to be included in this chapter, the codes can be

found in the appendices of NAVSUP P-485.

The following general rules apply to

MILSTRIP requisition:

Enter data by ball-point pen or typewriter. Do not use pencil; pencil

marks can cause errors when the

requisition is processed through mark

sensing equipment.

Data should be entered between the "tic" marks on the form. However, it is

mandatory that entries be included

within the data fields to which they

pertain.

To eliminate confusion between the numeral zero and the letter "O," use

the communications zero (f) on MILSTRIP

requisitions when zeros are applicable.

Specific details for completing DDForm 1348 and

NAVSUP Form 1250-1 can be found in NAVSUP

P-485.

MATERIAL RECEIPT, CUSTODY, AND STOWAGE

For every procurement action taken, there is a

receipt action that follows. Once the supplies are

received, they must be identified, checked,

and distributed to the appropriate

storeroom or department, and

documentation as to their receipt, custody and

stowage must be accomplished.

Material Receipt

As in every situation, responsibility for actions

taken must be assigned to key personnel. In the receipt

of government-owned materials,

responsibility for receipts takes on an

added importance because of the many

types of material receipts and the required

accountability.

Receipt Documentation

There are several types of receipt papers, and

which type is used depends upon the manner in which

the material was requested, the issuing

activity, and the modes of

transportation used in delivery. The most

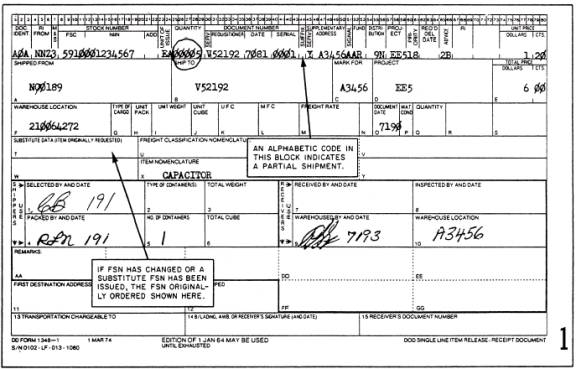

commonly encountered receipt is the DoD Single Line

Item Release/Receipt Document, DD Form

1348-1, (fig. 13-6). Regardless of the

type of receipt document, the end-use

receiver must

1. date the document upon receipt,

2. circle the quantity accepted, and

3. sign the document to indicate receipt.

Receiving Procedures

Small quantities of stores received on a daily basis

require no special preparations for receipt.

Stock large quantities of stores in a

central area out of the traffic flow

and hold there until preliminary identification

and package count are completed. Then sort them

according to the department or storeroom to

which they will be distributed.

Report of Discrepancy

Item or packaging discrepancies attributable to the

shipper (including contractors,

manufacturers, or vendors) should be

reported on the Report of Discrepancy

(ROD), SF 364, by the receiving activity.

The purpose of the ROD is to determine the cause of

the discrepancy, effect corrective action,

and prevent recurrence. When both item

discrepancies and packaging

discrepancies are noted on the same

shipment, both blocks on the top of SF 364 should be

checked and the types of discrepancies

noted. The types of discrepancies

required to be reported are described

in chapter 4 of NAVSUP P-485. Detailed

instructions for preparing and distributing of RODsare

contained in the current version of

SECNAVINST 4355.18.

Custody

The term custody refers to the responsibility for

proper care, stowage, and use of Navy

material and records pertaining to

such. Stored material is required to be

kept under lock and key, except when the material

is too numerous or too large to make such stowage

impractical. Lock storeroom spaces securely

when not in use.

Stowage

Material in storerooms and other designated

stowage areas should be arranged to

ensure maximum use of available space,

provide orderly stowage and ready accessibility,

prevent damage to spaces or injury to personnel,

reduce the possibility of material loss or damage,

make it easy to issue the oldest stock first, and

make it easy to inventory.

The preceding criteria and a "common-sense"

approach will enable storeroom personnel to achieve

stowage efficiency. To the maximum extent

that available space permits, you

should adhere to the following

guidelines when stowing material:

Locate heavy bulk material and materials handling equipment near hatches

or doors to minimize the physical effort

required for loading, stowage, and

breakout.

Figure 13-6.-DoD Single Item Release/Receipt Document, DD Form 1348-1.

Locate light bulky materials in storerooms with high overhead clearances for

maximum use of available space.

Segregate materials that are dissimilar in type or classification.

Locate frequently requested materials as close as possible to the point of

issue.

Locate shelf-life items in a readily accessible area to facilitate periodic

screening.

Install appropriate stowage aids (flashlight, paper, and pencil) in spaces

where they are readily accessible.

Make aisles at least 30 inches wide, if possible.

Arrange material with identification labels facing outward to make issue and

inventory easy.

Avoid multiple locations for the same item.

If you follow the preceding criteria and guidelines,

you should have no problems in maintaining your

spaces and issuing and inventorying

materials.

|