|

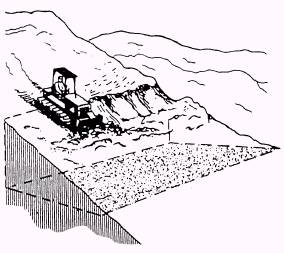

Sidehill Excavation A sidehill excavation can be started more easily if a small bench cut is made first, as shown in figure 11-33. When digging the sidehill, keep the inside (uphill)

Figure 11-33.-Bench cut. surface slightly lower to gain greater tractor stability (fig. 11-34). Tilting the blade produces this type of cut.

Figure 11-36.-Finishing a side slope by working parallel to the right-of-way.

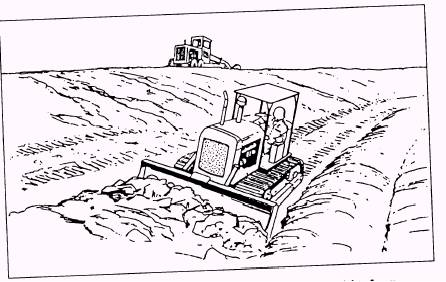

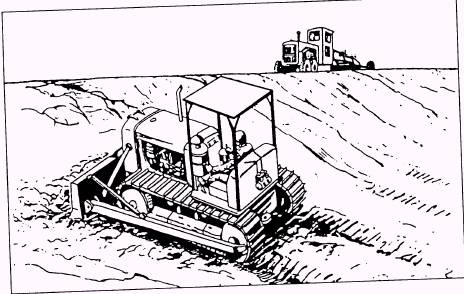

Figure 11-37.-Finishing a side slope by working diagonally. Always cut the shelf wide enough to provide solid support for equipment that will be used later. If possible, move the material downhill to gain the advantage of gravity, to reduce effort, and to increase the stability of the dozer. On shallow slopes or in soft soil, the sidehill cut can be made, as shown in figure 11-35, cuts 1 and 2. Stability is increased by running the uphill track inside the ridge left by the first cut. Cuts 3, 4, and 5 show the completion of the shelf. Pushing the loosened material to the lower side of the slope normally reduces the time required to complete the cut. Do not push the material beyond the point required to retain firm track support. When you are backing up, do not raise the blade, as this puts extra weight on the front idlers, causing greater track penetration. Let the blade float as you back away from the edge of soft fills. Finishing Side Slopes Two commonly used methods for finishing side slopes with dozers are shown in figures 11-36 and 11-37. When side slopes are finished by working parallel to the right-of-way (fig. 11-36), the dozer starts at the top. Material from each pass falls to the lower side of the blade and forms a windrow that is picked up on succeeding passes, filling irregularities in the terrain. Do not allow the blade corner to dig, since this steepens the slope beyond job specifications. In finishing side slopes by working diagonally, start the dozer at the bottom and work diagonally up the slope (fig. 11-37). A windrow is formed and is continually drifted to one side, tending to fill low spots or irregularities. NOTE: Diagonally finishing a side slope is one of the few instances when a dozer maybe used efficiently in cutting upgrade. Push Dozer The push dozer in figure 11-38 is equipped with a push blade. However, in most cases, a straight-blade dozer that has a reinforced block in the center of the blade is used. Ensure the center lines of the pusher and scraper are aligned. If alignment is not centered, it is hard to keep the pusher straight without extensive use of the steering clutch. When you are using the steering clutch, power is taken away from one track, and the other track is doing all the work. If the scraper starts to jackknife, stop pushing, back up, and get repositioned straight with the scraper. Be sure the blade of the dozer does not cut the rear tires of the scraper, resulting in downtime and costly tire replacement.

|