|

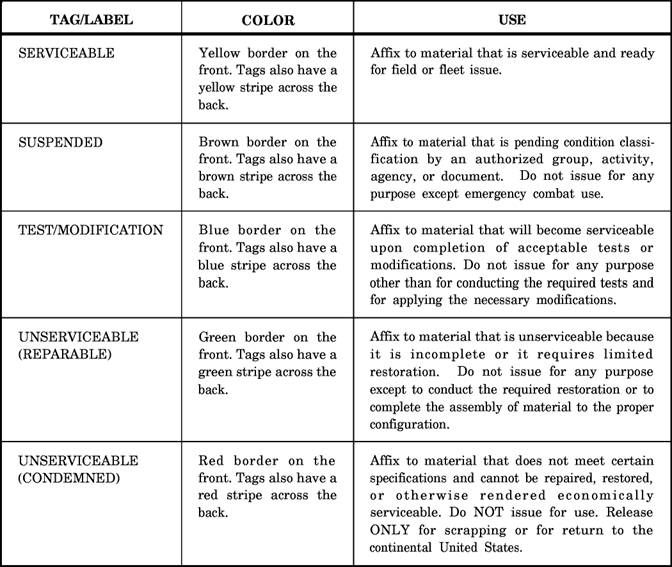

MATERIAL CONDITION TAGS AND LABELS Material condition tags, shown in figure 2-1 are used to indicate the

inspection and condition status of ordnance material, except for that material

in process that has accompanying material condition status documentation.

Material condition tags and labels must be affixed to the material so that they

permit easy identification of the material's condition. When it is impractical

to tag each item (i.e., nuts, bolts, resistors, etc.), then the container, rack,

bin, or drawer should be tagged or labeled.

Material condition tags and labels are filled out by the person affixing the

tag or label to the material.

Periodically, QA personnel monitor that process. However, all tags and labels

on material identified as serviceable are authenticated by a QA inspector, who

applies a QA inspection stamp or a signature to the tags and labels. When the

condition status of material changes, the material condition tags or labels are

changed to show the new status. The older tags and labels are removed, the

serviceable tags and labels are submitted to the QA department, and all other

tags and labels are destroyed by the person removing them.

Table 2-1.-Material Condition Tags and Labels

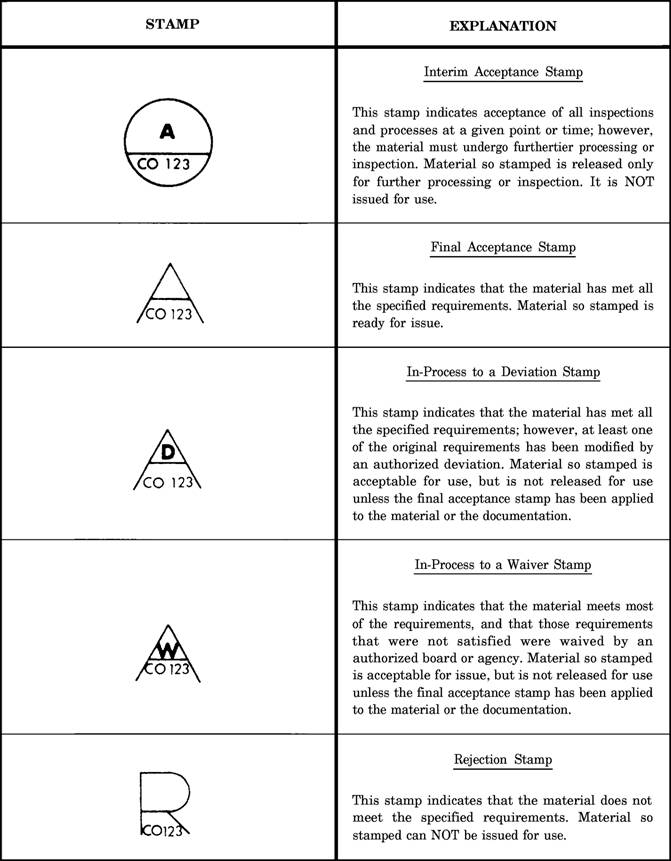

Table 2-2.-Inspection Stamp

|

|