|

HANDLING LOTS

The main problem with handling lots in the laundry is identification. You need to have a good system of identification in the ship's laundry to prevent loss of clothing during the workflow process. There may be several personnel handling

the clothing and proper identification is essential.

IDENTIFYING BULK LOTS

The clothing in bulk lots should be delivered to the laundry already stenciled. Each enlisted

person is responsible for stenciling his or her own clothing. The laundry petty officer in each division should accept only properly stenciled clothing.

Both black and white stencil pens usually are available in the retail store. Proper stenciling of clothing ensures proper distribution from the laundry. If the laundry supervisor runs into problems with lost clothing and claims, he or she may want to control the items turned in and return these items to each person. The laundry petty officer can list all articles across the top of a sheet of paper and write the people's names in a column down the left side of the sheet. The number of each article sent by each person should be entered in the box opposite the name and below the article. When the articles are returned to the individuals, the names are

checked off the list. If all articles are properly stenciled before they are sent to the laundry, this type of control will generally be unnecessary. Once bulk work is accepted it is the responsi-bility of the laundry to make sure it is properly identified from start to finish. You do not have to identify individual items in bulk lots brought to the laundry, but you do need to put some type of marker with each lot so that you can identify it during any phase of processing. You can make your own markers, or flags, from a duck fabric. Cut squares about 8 to 12 inches and hem them. Then stencil one marker for each division, service group, or any activity that brings bulk work to you. When bulk lots are brought to the laundry,

put the proper identification markers on them. You can use the same markers week after week. In addition to these markers, the division/ department name should be stenciled on the side of the bag in case the marker gets lost during the process. In the event you are required to split a lot, put the right markers on every part of it. All markers remain with lots and portions of lots during the complete washing and processing cycle. Put the marker in the washer with the load, and identify the load on the shell of the washer with chalk. If it is necessary that you put more than one lot in the washer to get full capacity, use a proper size laundry net for the smallest lot. When more than one net is required for the same lot, use a marker for each net. All soiled divisional bulk bags delivered to the laundry should be kept separate from clean laundry. In smaller laundries where space is

limited, an effort should be made to have all clean laundry picked up after it is completed. IDENTIFYING INDIVIDUAL LOTS

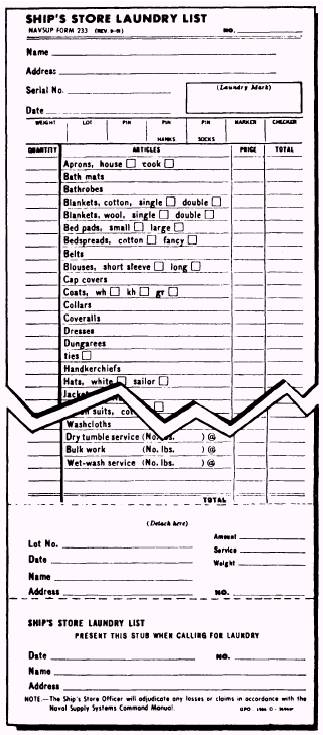

Ship's laundries use a Ship's Store Laundry List, NAVSUP Form 233, so officers and CPOs may identify what they have sent to the laundry (fig. 5-7). Normally, the form contains blanks at the top for the name of the ship, name of customer, rank or rate, social security number, date, and laundry mark. There is usually space for a Customer's-Count column and a Laundry-Count column, aligned with the list of articles. The customer fills in the lines at the top of the laundry list, enters the number of each article in the appropriate block, puts the laundry list with the laundry, and turns it over to the laundry receiving clerk.

Figure 5-7.- Ship's Store Laundry List, NAVSUP Form 233. In conjunction with the laundry list, laundry net bags should be used for the purpose of keeping rough-dry clothing together during the laundry process. They are open-mesh bags made from cotton or nylon in which the clothes are placed

for washing. Nylon nets have generally replaced cotton nets. They resist chemicals better than cotton and thus last longer. They also increase the

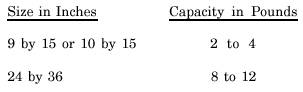

payload. You can do effective washing with laundry nets, provided you do not overload them. You must give the water and soap a chance to get to the clothes in order to remove soil. Nets are especially useful for separating small items such as handkerchiefs or socks from the larger articles. There are two general types of nylon nets- woven and knitted. Woven nets do not stretch and thus retain their size; knitted nets have a tendency to stretch and increase in size. For this reason, the range of knitted nets in

capacities is given below:

Steps in Identifying Individual Lots

The procedure for identifying items in individual bundles described in detail herein has been used successfully in shipboard operation. You may be able to modify this procedure to fit your own needs. The steps in the procedure are as follows: 1. Work on ONLY ONE individual bundle at a time; this prevents mixing of items from several bundles.

2. Remove the laundry list from the bundle

and determine from the individual's name and social security number what the laundry mark will be. This mark is made from the first letter of the individual's last name and the last four numbers of the individual's social security number. For example, the laundry mark for SHCM Frederick M.

Wishnacht, 123-45-6789, would be W-6789. This is the standard type of laundry mark used throughout the Navy. 3. Set the individual's laundry mark on the marking machine and stamp it across the face of the laundry list. Check the mark for accuracy. This list now denotes ownership of laundry in the bundle.

4. Count every article in the laundry bundle and enter the number in the correct block on the laundry list. If your count does not agree with that of the customer, ask the senior laundry man to recheck it. When the senior laundry man's count

is in disagreement with that of the customer, he or she should enter the correct count on the laundry list, circle the customer's count, then initial the circle and notify the customer of the change through whoever brought in the laundry

bundle.

5. Check each article for a correct legible mark. If there is not a mark, put ONE ONLY in the proper place (explained later). Do NOT mark such items as bath towels, wet articles, or dark-colored fabrics. Use pronged marking tags on these items. These tags are narrow strips of cloth approximately 1 inch long with metal fasteners in the ends. Push the metal fasteners through the material and press them flat on the other side. Enter the correct identification on the tags.

6. Check the inside of all pockets for any articles such as pens, pencils, lighters, combs, and so forth. If any items are found in the pockets, a notation should be made on the NAVSUP Form 233, Ship's Store Laundry List, and also in the laundry logbook so these items can be returned to the owner.

7. Check all articles of clothing for any tears,

stains, missing buttons, and so forth. Any items found to be damaged should be noted on the reverse side of the laundry list and also in the

Remarks column of the laundry logbook. 8. Clear the laundry marking machine by setting all type to the neutral position when you finish with one bundle. You are ready to start on another bundle.

|

|