|

WATER SOFTENING METHODS

The methods generally used to soften water are known as the base exchange and distillation. The base exchange method softens water when the compounds of calcium and magnesium in the water are exchanged for compounds of sodium which do not cause hardness. The distillation method softens the water when it is boiled and the vapor is cooled by running it through pipes immersed in a cold solution to reconvert it to water. The distillation method is used to make seawater usable for a ship's boilers and other shipboard uses. Seawater distillate is not pure water, but it contains only about 1/ 20,000 of its original concentration of salts. LAUNDRY DETERGENT

The detergent/ oxygen bleach is intended for shipboard laundering of cotton, synthetic, and blended items using fresh water or seawater. It is referred to as the two-shot detergent because

it includes a detergent and oxygen-based bleach and is mixed and ready to use. Since it is premixed you won't have to proportion laundry chemicals

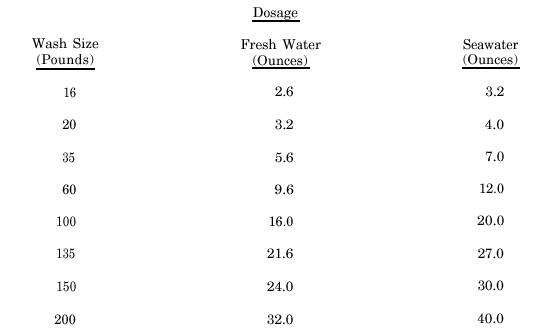

as in the past. As long as you add the correct amounts to the washer, the chemical proportion will be correct. Figure 5-9

shows the wash sizes and the amounts of two-shot detergent that should be used with fresh water and seawater. The two-shot detergent uses an oxygen-based bleach that is safe in washing all fabrics, therefore, the problem in damaging colored clothes with bleach is eliminated. The bleach is an integral part of the detergent and will not require special handling as it is not reactive to the other ingredients in the formulation. The detergent/ oxygen bleach releases a sharp, unpleasant solvent-type odor into the air while being used.

You should not be alarmed by this smell because the smell will not be transferred to the clothing. WASHING FORMULAS

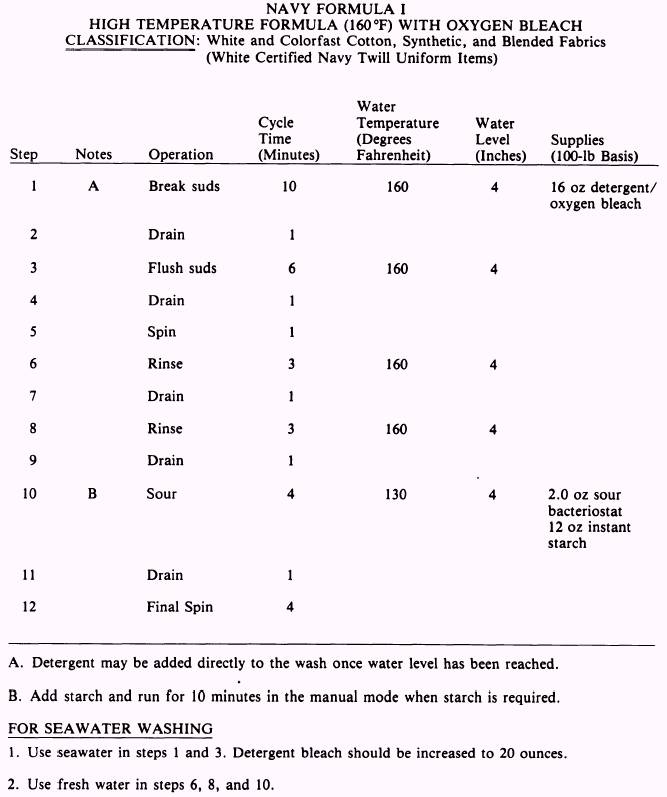

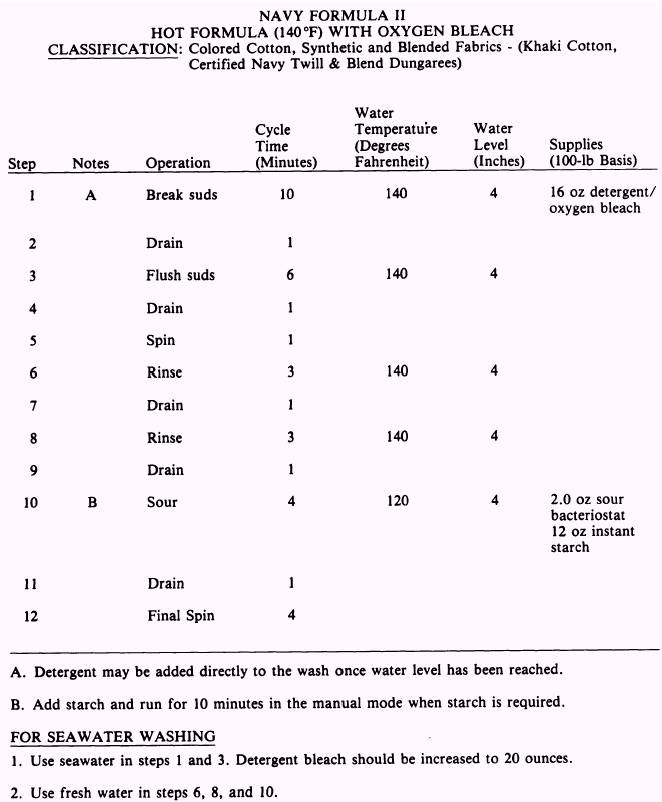

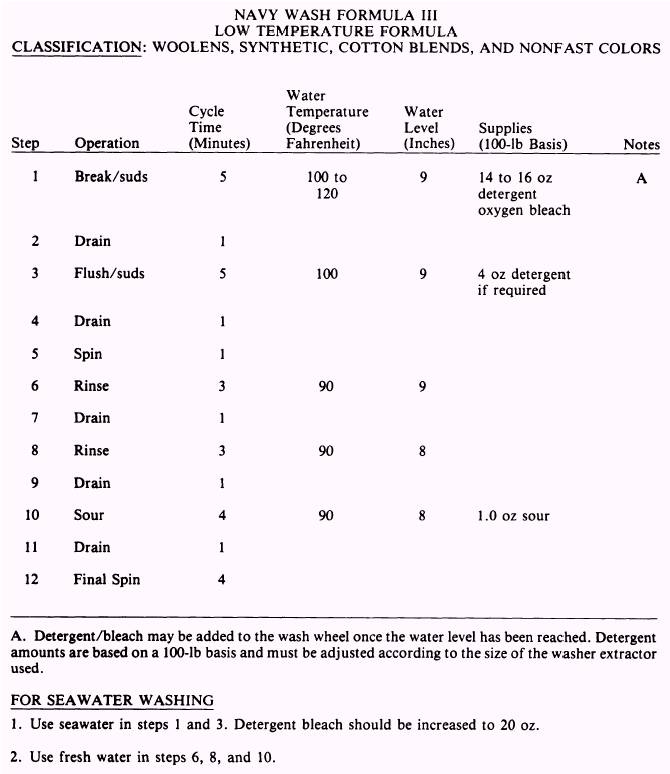

The Navy recently changed all Navy wash formulas to include the two-shot detergent. The new wash formulas were developed by the Navy to help shipboard personnel produce whiter and brighter washes. The formulas are illustrated in figures 5-10 through 5-12. These formulas have been tested in laundries aboard ship and have been found satisfactory for the type of work indicated. These formulas were developed to conserve energy and to meet environmental regulations while providing quality laundry. These formulas should be posted on the wash deck for laundry personnel to read and follow. RINSING

Rinsing removes soil and cleaning solutions from the clothes. Poor rinsing results in grayness, disagreeable odors, harsh finish, and generally poor quality work. The number of rinses used should always be according to the Navy wash formula you are using and should not be modified. Under normal conditions, following the Navy wash formula in regards to the number of rinses, the rinse water levels, water temperature, and time of running will bring desirable results. If clothes that are heavily soiled do not come out clean in the first wash they should be washed again according to the Navy wash formula. LAUNDRY SOUR

Laundry sour is added to the last rinse to neutralize the remaining alkalies and to dissolve

Figure 5-9.- Two-shot detergent amounts.

Figure 5-10.- Navy wash formula I.

Figure 5-11.-Navy wash formula II.

Figure 5-12.- Navy wash formula III. iron and other metallic salts that cause rust or a yellow discoloration. If left in fabrics these chemicals cause odors and discoloration after drying. Another reason for using a sour in the last rinse is that it removes sodium bicarbonate, which is normally in the rinse water. Even though other chemicals may have rinsed out, sodium bicarbonate remains. It is not injurious to fabrics in itself, but when subjected to the heat of flatwork ironers, presses, or hand ironers, it is converted to sodium carbonate which is quite alkaline and in sufficient concentration can cause injury to fabrics.

Souring also decomposes any oxidizing bleach left in a load, prevents discoloration, and helps to sterilize the clothes. In addition, sour sets acid dyes often used in bright-colored fabrics and preserves the tensile strength of fibers. Laundry

sour also removes rust stains. There are many different laundry sours of varying strengths, including acetic acid, fluorosilic acid, hydrofluoric acid, and several types of fluoride (ammonium, sodium acid, and sodium

silico). Fluoride is generally used. The sour required for use is combined in the powdered form with powdered blue

(NSN 7930-00-205-2882).

|