|

STARCH

Starch is applied to wearing apparel and other linens to give them body, smoothness, and an improved appearance. Only cotton fabrics should be starched in the ship's laundry. DO NOT starch synthetic and synthetic blend fabrics or work clothes. The amount of starch used should be the amount indicated on the formula. Starching should only be done in the automatic mode; however, when you have to do it manually, follow these steps: 1. Do not drain the sour/ blue bath. Reduce water to a low level with the water at temperature indicated on the formula. Add the proper amount of starch.

2. Run the machine for 4 minutes, long enough to allow the starch to penetrate the shirts.

3. Drain the starch from the machine while it is running to prevent the starch from settling on the load. WASHER EXTRACTORS

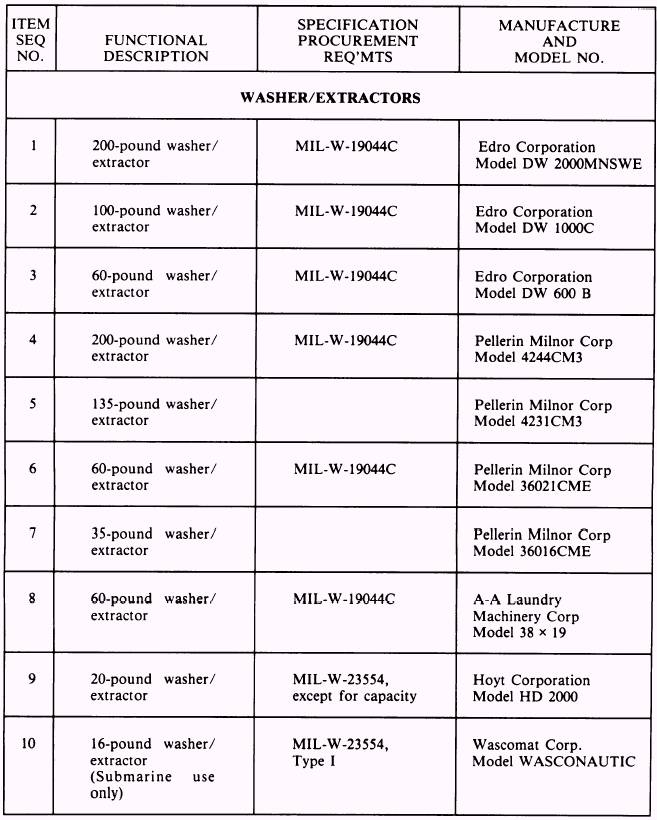

Washer extractors installed aboard ship differ mainly in load capacity. The Naval Sea Systems

Command (NAVSEA) publishes the Navy Laundry and Dry-Cleaning Equipment Catalog (Tech Manual #S6152-B1-CAT-010). This catalog is used by the Navy to obtain information for identification, selection, and procurement of standard naval shipboard laundry and dry-cleaning equipment. The washer extractors used

by the Navy are listed in figure 5-13. This catalog includes several different types and sizes of washer extractors, however, the Edro

(Dyna Wash) and the Pellerin Milnor washers are the ones most widely used by the Navy.

Washer extractors are basically made up into two parts, the outer shell and the cylinder. The shell holds the water and cleaning ingredients, while the cylinder hold the clothes. The cylinder is perforated to allow water and suds in the bottom of the shell to enter and clean the clothes during the wash cycle. The washer extractor then extracts the water from the cylinder by using centrifugal force. A separate extract motor spins the cylinder at a high speed to do this. OPERATION OF THE WASHER EXTRACTOR (EDRO MODEL)

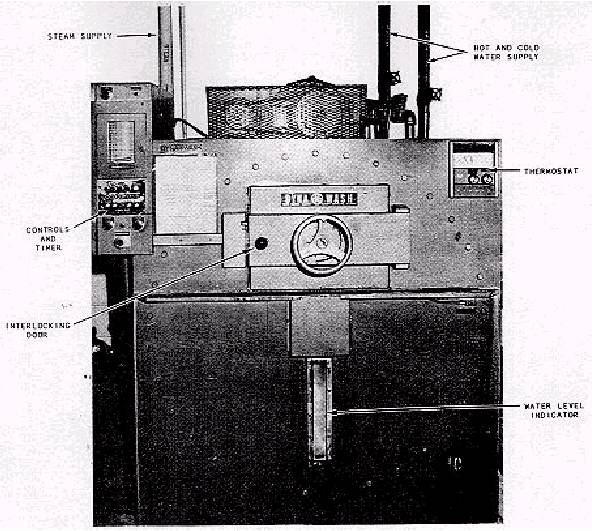

The washer extractor manufactured by the Edro Corporation, better known as the Dyna Wash, is procured in three sizes- 200-, 100-, or 60-pound sizes. The 100-pound Dyna Wash (including basic parts) is illustrated in figure 5-14. This washer extractor was designed to provide an easy and safe method of washing clothes, therefore, training personnel to operate the

machine is easy. Since the washer extractor is automatic, the only thing the operator will have to do is load, add supplies, and unload. WASHER EXTRACTOR CONTROLS

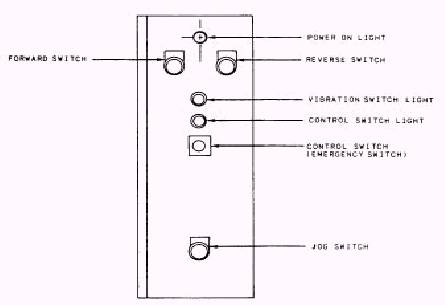

The Dyna Wash control system consists of two parts, the control panel and the programmer. The control panel is illustrated in figure 5-15.

This panel may look slightly different on some models; however, the purpose of the basic controls on this panel is the same. The control switch energizes all electricity to

the control panel and programmer. This control switch must be energized before you can use any of the basic controls. The basic controls on

the control panel are used when loading and unloading the washer. By depressing the jog switch simultaneously with the reverse or forward

switch, the washer cylinder will rotate in that

Figure 5-13.- List of washer extractors used.

Figure 5-14.- 100 pound washer extractor basic parts.

Figure 5-15.-Layout of a washer extractor control panel. direction until the cylinder door is lined up with the outer shell door. The programmer is illustrated in figure 5-16

and lists all major controls and indicators. The drain indicator and switch open or close the drain and indicate when it is in use. Depress the cold or hot water indicators and switches to add cold or hot water. A light on the panel indicates when the programmer is in use. The master and timer indicator lights are used in conjunction with the operation of the timer. Once these two switches are energized, the timer wheel begins to move. The wash indicator light is also used in conjunction with the master switch for operating the machine in the manual mode. The steam indicator and

switch are used to emit steam to the machine in the manual mode or indicate steam is being added by the light being lit during the automatic mode. The signal indicator light and switch light up and sound a bell when the automatic cycle is complete to alert laundry personnel. The extract indicator

light and switch are used to energize the extract motor during the manual mode and light up when extract is being used during the automatic mode. A microswitch is installed inside the

pro-grammer to protect the user. Once the door to the programmer is opened, the microswitch pops out and de-energizes the circuit to prevent electrical shock. The drum control disk is used

to manually turn the program wheel around. As you can see there are several controls, however, if you run the machine automatically the way it was intended, you will never have to use most of them.

|