|

DESCRIPTION OF THE PROGRAMMER

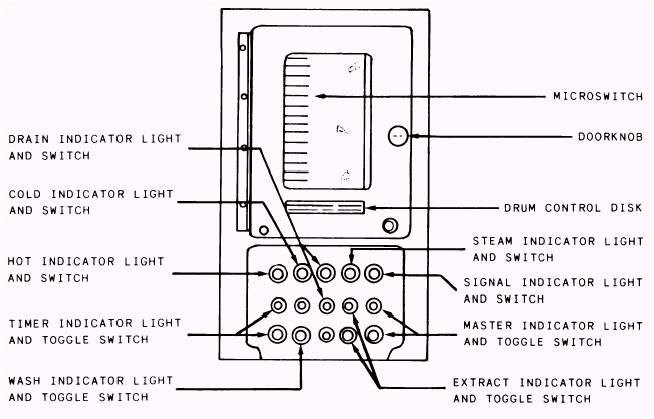

The operation of the programmer is controlled by energizing the control switch on the control panel and then energizing the master and timer switch on the programmer. (See fig. 5-16.)

A program chart is cut to conform with Navy wash formulas and is installed on the control disk wheel inside the programmer. Also inside the programmer are fingers that drop into grooves that were cut in the program chart. Once these

fingers come in contact with the metal on the disk, they energize that particular operation. The disk continues to rotate until the timer switch is off or when one of the following occur:

Figure 5-16.- Layout of washer extractor programmer. The disk stops until proper water levels are reached.

The disk stops until correct water temperatures are acquired during steam injection.

The disk stops while adding supplies from the automatic dispenser.

The disk stops when the signal goes on.

After the completion of the cycle and when the signal alarm goes off, the timer switch should be de-energized to prevent the chart from advancing again. PROGRAM CHART

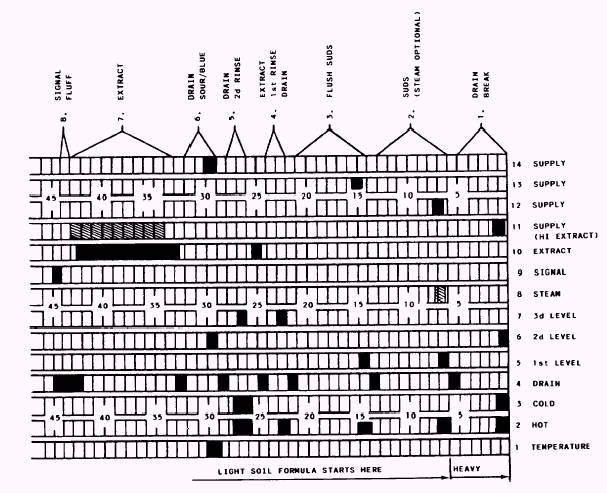

In conjunction with the wash formula, a program chart is cut according to the Navy wash formula. These charts, available through the supply system, are used with the automatic programmer on the washer extractor to make sure

the Navy wash formula is followed to the letter. Your local fleet assistance team is available to provide assistance in cutting the chart. A sample program chart is illustrated in figure 5-17.

Keep in mind this is a sample chart only and should not be referenced in cutting your own chart. Temperature Control

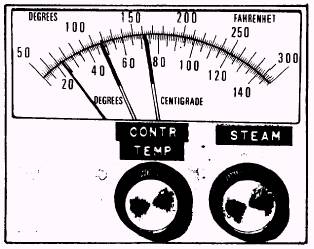

This control on the program chart regulates the temperature of the water. The desired temperature of the water in the washer extractor is controlled by a thermostat located on the

Figure 5-17.- Sample program chart. washer itself (fig. 5-18).

This thermostat can control two temperature settings, the high temperature for washing and the low temperature for sour. The low temperature is controlled by

turning the black pointer on the thermostat to the desired temperature setting. Once the temperature control slot is reached on the program chart, hot water is added to the washer and tempered with cold water to reach the desired temperature you set on the thermostat. The desired temperature will always be the lower temperature on the Navy wash formula.

To set the high temperature, move the red pointer on the thermostat to the high temperature setting on the wash formula. During the break

suds, hot water is admitted into the washer. The hot water stops when water levels are reached and then steam is admitted until the high temperature is reached. The third pointer in the thermostat indicates the actual temperature in the washer. Water Levels

Water levels in the washer are controlled by slots 5 through 7 on your program chart (fig.

5-17). Wash formulas are based on certain amounts of water. If the amounts are other than indicated, your concentration of supplies will not be correct. Water levels are preset at the factory; however, they may have to be adjusted to conform to Navy wash formulas. Water levels

should be reached before steam is admitted into the washer. If you notice steam being admitted into the washer before water levels are reached, the cutting of the program chart should be rechecked.

Figure 5-18.- Washer extractor temperature control. Automatic Supply

The automatic injection of supplies into the water is done by slots 11 and 12. The automatic supply bins that are located on the right side of the washer extractor contain four bins. Navy wash formulas I and II require three supplies and Navy wash formula III requires two supplies. Therefore, you will only use two bins because sour and starch can be added together. This means only two of the four slots on the program chart will be cut to allow these supplies into the washer drum.

|