|

SAFETY FEATURES

All laundry personnel should be familiar with washer extractor safety features to prevent personal injury and/ or damage to equipment. The laundry supervisor should prepare a locally prepared document that covers all safety features noted in the equipment technical manual. The safety features listed below are generally true for all models; however, check your technical manual for any additional safety features.

1. During the wash cycle the washer extractor will cut off if the outer shell door is opened.

2. The outer shell door of the washer extractor will not open during the extract cycle because of an interlock switch.

3. Both hands must be used to operate the jog switches on the control panel.

4. The control switch on the control panel or the master switch on the programmer can be used as emergency stops.

5. The vibration switch is installed to stop incorrectly loaded machines during extract.

6. The air pressure switch will not allow the machine to operate on less than 50 pounds of air pressure for the wash cycle and 80 pounds of air pressure for extract.

7. The automatic brake engages during power

loss or emergency stop.

8. The positioning interlock switch is installed to eliminate the possibility of having the wash motor activate while the outer shell door is open. PREOPERATIONAL CHECKS

Before actually operating the washer extractor, be sure you are ready by doing the following: . Check your steam supply (100 pounds is ideal).

Check to make sure you have fresh water.

Check your air pressure (the washer extractor will not operate if less than 50 pounds).

Make sure all other switches are off when you energize the control and master switches so nothing else will energize.

Turn equipment on; check for response (lights, dump closed, and so forth).

Check the cylinder door; make sure it is secured.

Check the thermostat for proper tem-perature settings. AUTOMATIC OPERATION

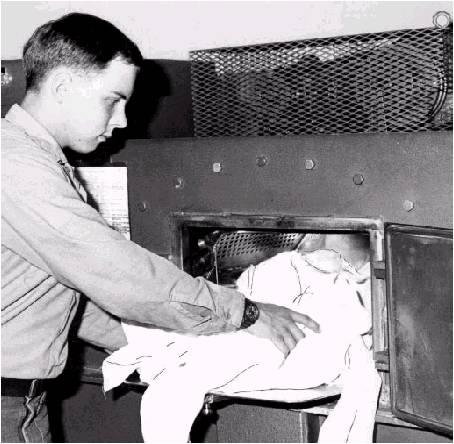

Figure 5-19 shows a laundryman loading a Dyna Wash. Except for loading, unloading, and adding supplies all functions in the automatic mode are done for you. When loading the Dyna Wash, you should divide the wash load into three equal piles. There should be no more than a 10 percent difference in the weight of each pile. Overloading a washing machine is one of the chief causes of breakdowns because greater strain than the manufacturer intended is placed on all moving parts, particularly the motor. Overloading also results in poor washing because the water and cleaning solution do not have adequate space and sufficient agitation to remove soil. Underloading, on the other hand, results in a waste of water and cleaning supplies. You should, therefore, weigh every load of clothes for each compartment in the cylinder. Once you have done your preoperational checks, you are ready to operate the washer extractor using the following procedures:

Figure 5-19.-Loading the washer extractor. 1. Open the shell door.

2. Energize the control switch; make sure all other switches are in the OFF position before doing this function.

3. Rotate the cylinder with the jog switch,

used simultaneously with the reverse or forward switch until the cylinder door is opposite the shell door opening.

4. Turn off the control switch.

5. Open the cylinder door. CAUTION: NEVER place hands inside the shell or cylinder while the control switch is energized.

6. Load washer to rated capacity.

7. Mark on the washer with chalk what is

in each pocket (each cylinder door is numbered 1, 2, or 3).

8. Close the door to each cylinder; latch it securely.

9. Close the outer shell door.

10. Add required supplies to the automatic dispenser; make sure you place them in the correct bin.

11. Use the drum control disk to set the programmer chart to the beginning; make sure the master switch to the programmer is off while doing this.

12. Energize the control switch, master switch, and timer switch (in that order). From this time on, the operator normally will not have to return until the signal sounds. The bell to this signal can be silenced by securing power or depressing the button.

|