|

MANUAL OPERATION

If the automatic timer is inoperative, you will have to operate the machine manually. Manual mode should not be used when the washer timer is operating properly. The controls and switches as mentioned earlier when used properly allow the operator to use the manual mode. Looking back at automatic operation you should follow all steps up to and including step 9 and then follow these instructions: 10. Turn the control switch on.

11. Start the wash motor by energizing the wash and master switches. 12. Make sure all other switches are off and the drain switch is closed. 13. Add water to the proper level and at the proper temperature, as indicated on the wash formula. If the water is not hot enough, use steam to bring it to the desired temperature. 14. Add chemicals as prescribed by the washing formula, through the supply door when the cylinder is passing the supply door in the downward direction. 15. Start timing the bath (follow formula).

16. Open the drain switch and drain the water when time for each cycle elapses. 17. Permit sufficient time for the water to drain from the shell after the water level reads zero, and then close the dump valve. 18. Repeat steps 14 through 17 until the wash formula reaches the extract cycle of the formula. 19. Leave the valve open for more complete drainage after the last bath. 20. Start the extraction cycle. Move the switch to extract position. When extraction is completed, move the switch to WASH or INCH position as desired. 21. Secure the power, loosen the handwheel, and open the outer shell door only after the washer cylinder comes to a complete stop. Use the jog switch to align the cylinder doors, then open and unload each pocket. LOADING AND UNLOADING

Before the wash in the washer extractor is done, attending laundry personnel should have three piles of sorted and weighed soiled laundry ready for loading. The unloading process is just the opposite of the loading process. Make sure when you open the outer shell door that the cylinder has come to a complete stop and all switches are de-energized. You are now ready to line up the cylinder doors with the outer shell door

for unloading purposes. CAUTION: NEVER stick any part of your hand or arm inside the shell door if any of the washer extractor controls are energized. After unloading the freshly laundered clothing, it should be routed to the next processing station and the presorted and weighed soiled laundry loaded. The clean laundry should be

routed swiftly to prevent it getting mixed up with other laundry. It is either routed to the press deck for processing on the presses or flatwork ironer or placed in the dryer for drying.

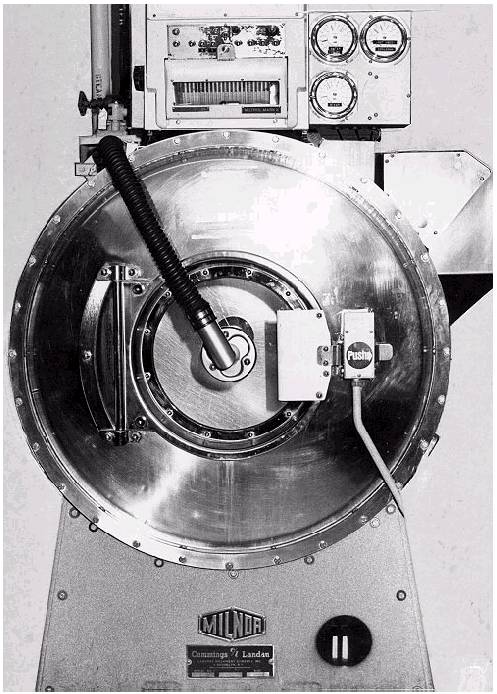

Figure 5-20.-Milnor washer extractor, 60 pound.

OPERATION OF THE PELLERIN MILNOR WASHER EXTRACTOR

A 60-pound Milnor washer extractor is illustrated in figure 5-20. Like the Dyna Wash it is fully automatic, saving the operator the trouble of manual operation. The operating procedures are different from the Dyna Wash and you should be familiar with them.

|