|

OPERATION OF THE LAUNDRY PRESS

Presses are air operated and controlled by push buttons mounted flush with the front of the press table. The air buttons located on the front of the table are used for lowering, locking, and releasing the head. The two outside red buttons lower and lock the head. Both hands must be used to press both buttons at the same time. The release buttons are the two inside green buttons. The head can be released by depressing either the right or left inside release button. Before you operate the press, examine the cover and padding before heating it. Then check the head pressure by inserting a bedding sheet leaving a portion exposed and trying to pull it out after the press is closed. The bedding sheet will resist all efforts to remove it and remain in place in all areas. If the padding is bad, do not use the press until it is

repadded. If the cover is unsatisfactory, replace it with a new one. When you heat the laundry press, do it

grad-ually. Turn the steam valve partially open for 20 minutes and then open it completely. The press is then ready for use.

The time required to press and dry a garment satisfactorily is dependent upon the following: 1. Type of material

2. Moisture in the material

3. Steam pressure (less than 100 psi will require longer time)

4. Effectiveness of the steam trap in carrying away the condensed steam to allow unrestricted flow of live steam into the head chamber

5. Head pressure

An article with a rough, dry appearance usually requires more than normal pressing time. Be certain, of course, that the article is damp enough when you start to press it. If the article lacks sufficient moisture for good pressing, spray it with the spray gun. For normal pressing, keep the head down for about 15 seconds. Experience in pressing enables you to tell when to add dampness to a garment before you press it, and how long it will take to press that particular type of material.

SAFETY FEATURES

The laundry press head will not close unless you use both hands to push the two red buttons. This prevents getting your hand caught under the press head. Opening the press head requires pushing only one of the green buttons. This is done to allow easy release in an emergency. Also, press heads will not close and lock if an object too thick is between the press head and pad. This safety feature can be tested by taking a bed sheet, rolling it up in a tubular fashion, placing it under

the press head, and then trying to close the press head. If the press head is adjusted properly, the head of the press will not lock shut. Many incidents have occurred where laundry personnel have caught their hands between the

press head and the pad. If you follow a few simple safety precautions, this should never happen. l Never operate the press if any control buttons are sticking.

. Never plug one of the buttons with any device to increase speed.

. Do not allow anyone to stand near the press while operating it.

. Only one operator should be working at a press station at a time.

l Know the location of the main steam valve to the laundry in case of an emergency such as a broken steam line or steam leak. MAINTENANCE OF PRESSES

The laundry supervisor and operators should not only perform minor maintenance on presses, but also should see that repairs to presses are re-corded properly in the equipment maintenance log. The steam pressure to the presses should be 100 pounds per square inch. Some of the presses have pressure gauges. The air pressure on air-operated presses should be 75 to 95 pounds per square inch. In addition, engineering personnel should give the presses a hydrostatic test once a year. This test should be for 150 pounds per

square inch for 1 minute. Laundry personnel should not get into the mechanics of the laundry press; however, they should perform the following operator maintenance: 1. Thoroughly clean presses (daily).

2. Clean and wax press heads (as required).

3. Change pads and covers (as required). Early in the morning and just before pressing, you should use a foxtail to dust off the entire press table of the laundry press. Then take some hot, soapy water and completely wash off the press table and dry it. Always be careful not to bring your arms into contact with any of the heated surfaces of the press. CLEANING PRESS HEADS

Press heads must be clean at all times to prevent clothing from picking up stains that may be on the press head. To clean the press properly, you need press head cleaner, press head wax, and press head mitts. These products are available for procurement through the Ship's Store Contract

Bulletin. The main purpose of the press head mitt is to prevent laundry personnel from being burned. The press head mitt has two different sides, one side is smooth, while the other side is made of steel wool material. You use the smooth side to apply

press head cleaner to the press head evenly. Then scrub the whole press head with the steel wool side of the press mitt. Use clean rags to wipe the press clean and

always keep the press head mitt on to prevent bums to your hand. CAUTION: NEVER use rags that may have flammable substances on them. After you remove all excess press head cleaner, do the final touch by applying wax to the press head. Use a wax cloth to sprinkle wax on one side of the cloth and then fold it together. Use the press head mitt and wipe the cloth evenly against the press head until all surfaces have been waxed. Use a clean rag to wipe off any excess wax. Use an old bed linen to test the press head for excess cleaner or wax by lowering the press head on the sheet. If no stains are noticed you are ready for

regular pressing. CHANGING PADS

Presses must be properly padded at all times. Packed down pads produce poor quality work and break buttons, and clothing articles pick up burn odors when pressed on burned-out padding.

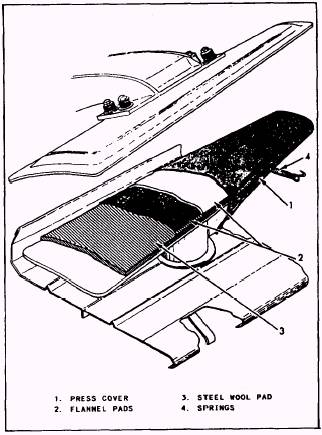

Change these pads as required. Figure 5-36 illustrates the materials you will need to change pads which includes the following:

l One steel wool pad

l Two flannel pads

. One press cover

Figure 5-36.- Changing laundry press padding.

The procedure for padding the buck is simple. Unclamp or unhook the cover beneath the buck and remove all the old padding.

The steel wool pad on the bottom is very expensive and needs to be changed only when worn or rusted (about once a year). On the top

of your steel wool pad, place the two flannel pads and then the press cover on top of them. Then pull the drawstring tight and tie it off. Connect all tension springs and clamps under the buck of

the press and you are done. Synthetic covers last longer than cotton covers. The drawstring in the cover helps to hold the

padding in place, but the tension springs on the clamps or hooks beneath the buck hold the padding firmly in place. They give an even pull all around the cover. Change covers when they become soiled or badly scorched.

Always use two layers of flannel on the press. One flannel pad does not cushion the garment well

enough and buttons may be broken. When two layers of flannel are used, change one layer each week. Place the new layer on the bottom and the used layer on top. You can wash double-faced flannel and reuse it. If the flannel shrinks, use it on a smaller buck. If the flannel becomes hard, apply steam to the surface and work it with the hand until the flannel becomes pliable. Tumbling also makes the flannel pliable.

Change the knitted padding when it becomes scorched or burned. No set time can be given for changing the knitted padding, but under normal operating conditions it should be changed about

once a month.

|