|

PRESS LAYS

In machine pressing, each garment is finished by a series of LAYS. Each lay is a position of the garment on the buck, and the series should cover the entire garment. Out-of-the-way places that cannot be pressed with the machine should be smoothed out with a hand iron. Sequences of lays for shirts and trousers are described on the following pages. The ones given are considered the minimum for each article when good quality pressing is desired. The lays,

however, are not standard with all pressers. For example, some laundry personnel use two lays for pressing the front of shirts, one with the pocket

flap up and the other with the flap down. Other pressers use one lay with the flap down and get accept able work. When determining the proper sequence of lays for a garment, take into consideration the following: 1. Minimum number of lays required to do the work satisfactorily

2. Logical sequence of lays, for easier and

quick handling

3. Part of the garment to be pressed last to prevent damage to the finish of the most conspicuous parts of the garment

The lays given for different articles below are now used in ships' laundries. The following lays for shirts and trousers do not include the use of a hand iron for touch-up work on places difficult

to reach with the press. When available, use these irons as necessary to get good quality work. A garment that is nearly finished should not be

handled too much in doing touch-up.

PRESS LAYS FOR SHIRTS

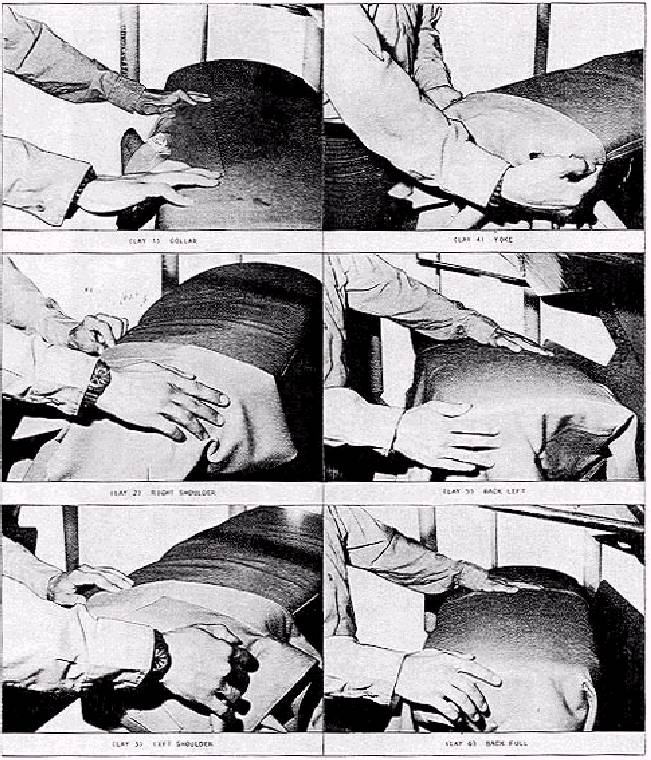

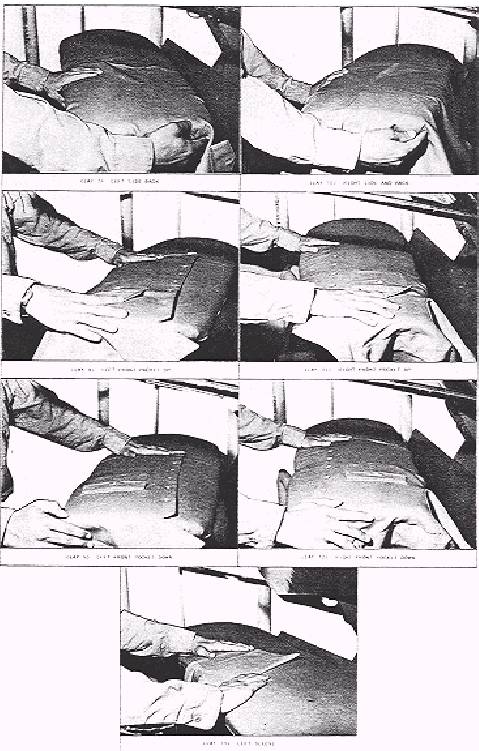

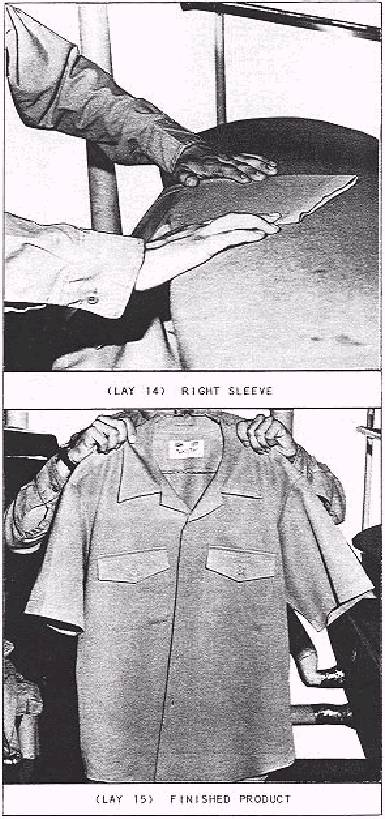

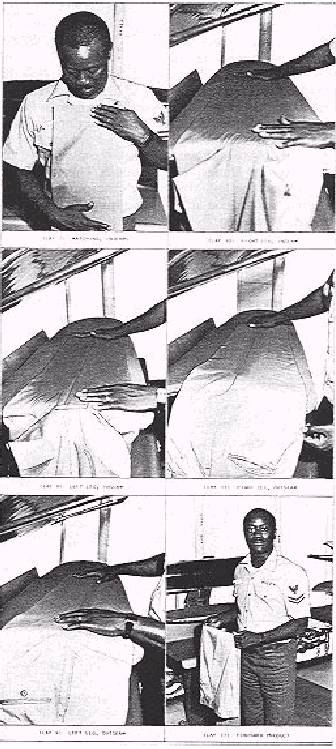

Figures 5-37 through

5-39 give the sequence of lays for pressing a shirt on presses available in shipboard laundries. The press lays shown are considered the minimum required in pressing a shirt properly. The first lay shows the pressing of a shirt collar on a standard press; it may be done on a collar/ cuff press if available. Laundries with a sleeve press may use it to

press sleeves in place of a conventional press. The pressing of the inside of the pocket should be done as shown in figures 5-37 through

5-39; however, on synthetic uniforms it is not necessary and pockets will normally not fold back. Synthetic and

synthetic blend uniforms should be finished in the dryer when possible as outlined in the drying section. Spray guns should be used when necessary to keep shirts damp during pressing. This also improves the finished appearance of the shirt, Any wrinkles that cannot be removed using the conventional press should be done by a hand iron. PRESS LAYS FOR TROUSERS

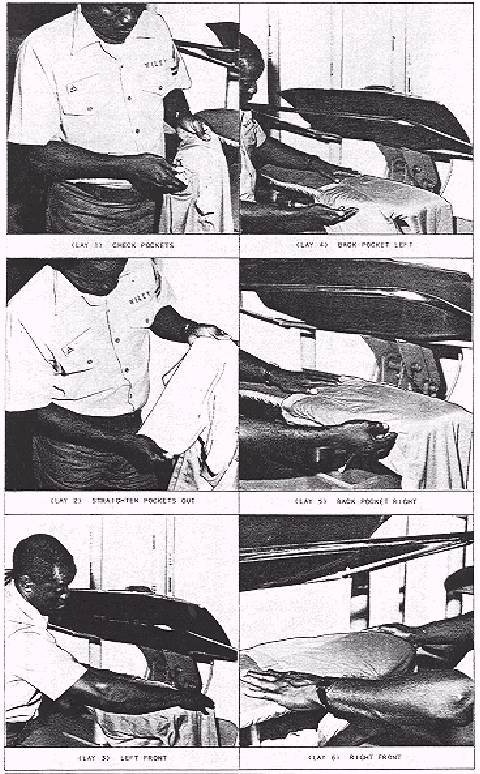

Figures 5-40 and

5-41 illustrate the press lays that are used for a pair of trousers. Remove the trousers from the damp box. (Keep a wet net over the damp box at all times.) Straighten out the trouser pockets as shown in the first two lays of figure 5-40.

Shape the trousers with your hand and dampen, if necessary. Then continue with the lays as shown. If the steam pressure in the laundry is below 100 pounds of pressure, you may have to press the trousers a bit longer to make sure all dampness is gone, especially for the inside pockets. When matching the inseams be sure the outer seam matches the inner seam on both legs. If they are not matched properly, the line will run uneven on the trousers. When you complete the press lays, hang the trousers on a hanger equipped with a

trouser guard to prevent lines from setting in the legs of the trousers during stowage. FINISHING OTHER ARTICLES

To finish cap covers you should use a regular iron and press the band on the small end of a press.

Press garrison caps in two lays on any type of press. Use one lay for each side. Do NOT press caps with leather bands on a laundry press, The leather will not withstand the temperature of the hot head. When you press ties, cut a cardboard form that will fit inside to hold them straight. Then press with two lays, one for each side. Do not press wool worsted ties on a laundry press. Use a press in the dry-cleaning plant, with a covered head.

Figure 5-37.-Lays for pressing shirts (lays 1 through 6).

Figure 5-38.-Lays for shirts (lays 7 through 13).

Figure 5-39.-Lays for shirts (lays 14 through 15).

Figure 5-40.-Press lays for trousers (lays 1 through 6).

Figure 5-41.-Lays for trousers (lays 7 through 12). Pressing dungaree shirts is done in the same manner as shown in shirt pressing; however, care should be taken when pressing the sleeve with the petty officer crow. This petty officer crow may cause a stain on the press head or press cover. To avoid this problem, you should place a piece of cardboard between the crow and the press head or cover. This prevents the petty officer crow from imprinting on the press head or press cover. Precondition dungarees in the dryer before pressing as discussed in the drying section. This is done because they hold a lot of water and on newer dungarees the blue color may fade onto the press cover, thus ruining the cover. Dungaree trousers are pressed inside out and the legs are pressed flat with creases going inward on the seams instead of in the middle of the leg. Care should be taken when pressing tablecloths or napkins. When a flatwork ironer is not available, these items will have to be pressed on a conventional press. The tablecloths and napkins should be preconditioned in the dryer before pressing (do not overdry). If the tablecloths and napkins are not preconditioned before pressing, they may scorch. On the other hand, if they are pressed too dry, they will not be finished properly. Tablecloths should be stored with a wet cloth over them until you are ready to press them or they will dry out.

|