|

AUTOMATIC PANTS TOPPER

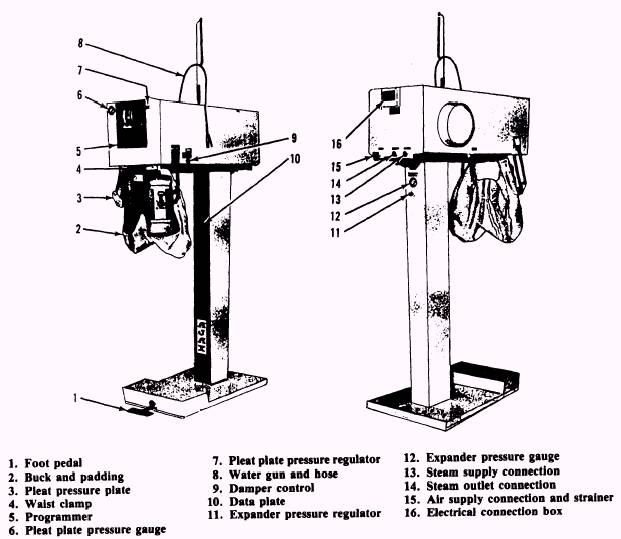

When available, use the automatic pants topper shown in figure 6-14

to speed up

Figure 6-14.-- Automatic pants topper. production of trouser tops. The automatic pants topper is quicker and eliminates the several lays required to finish trouser tops on a conventional press by using air and steam. Steam and air are set automatically and then released into the air bag for a desired period of time in which the trouser tops are finished. The pants topper can be run manually or automatically. Refer to your technical manual for correct operating procedures. ASSEMBLING AND ISSUING

When you finish pressing the clothes, you get them ready for issuing. Use the dry-cleaning lists for assembling articles into customer groups. The number on each master tag attached to the dry-cleaning list corresponds to the numbers of various articles in a customer's bundle. Put the tags in numerical order and collect all articles belonging to each master tag. Be sure that all articles written on the customer's dry-cleaning list are present and accounted for. Then check to see that all buttons are intact and that belts and buckles are present. Missing buttons should be replaced, and all belts and buckles presented to the laundry should be returned with the cleaned article or replaced when lost. After you collect and check all items that

belong in a customer's bundle, attach the dry-cleaning list, and put the items on the assembly and/ or issue rack in numerical order. As stated previously, the time for pickup by authorized persons is indicated on the dry-cleaning schedule. The hours are stated by divisions and activities and staggered to prevent congestion in the pickup line. Delivery periods should be at stated periods that will not interfere with active

dry-cleaning processes in the department. CARE AND MAINTENANCE OF THE DRY-CLEANING MACHINE

Keep the surfaces of machines in the dry-cleaning unit free of dust. Wash them with hot water and soap or a safe solvent. Apply a light coat of wax to the surfaces of new machines to help keep dirt from adhering to them. Clean the foam filter located in the lint housing daily by brushing the foam material to remove excess lint and washing it with clear water and squeezing it dry. Do not reinstall the filter when it is wet or use soaps or solvents when you clean it. Check for accumulations of lint on coils when you remove the lint bag in the evening. Clean the pump lint strainer once each week or more often under heavy use. Never remove this strainer for cleaning while the machine is running. Be on the alert for solvent and grease leaks. Occasionally, check the timer with a watch. Make sure main-tenance and lubrication charts are followed. Report requirements for maintenance to your supervisor. MAINTENANCE OF DRY-CLEANING PRESSES

The maintenance of dry-cleaning presses is basically the same as

laundry presses. Thoroughly clean them daily and change the pads and

covers as required. Padding is so important in the dry-cleaning

plant in order to produce a beautifully finished product. The

presses are padded in the same manner as conventional presses, one

steel wool pad (change once a year), two flannel pads (change the

oldest one once a week or as required), and one cover that can

either be changed when it shows signs of wear or taken off and

washed once a week. All other press maintenance should be done by

qualified maintenance personnel. Dry-cleaning personnel should not

attempt maintenance on the presses that they are not qualified to perform.

|