SPOTS AND STAINS

Many spots and stains are removed through the regular washing or

dry-cleaning process. Spots on clothing are caused by foods, blood,

grease, and so forth. When these spots become set in the material

they are considered a stain. The setting of a spot usually is caused

by heat or from certain chemical reactions. Once set it cannot be

removed without some injury to the fabric. In many cases the injury

is so minor that removal is still worthwhile. In other instances,

the risk of damage to the fabric is so serious that it's better to

leave the stain in the fabric. Therefore, as you will learn, it is

very important that spots are identified and treated before they

become a stain.

SPOTTING

Any stain that resists the normal washing or dry-cleaning

process can usually be removed using a special treatment called

spotting. Spotting is a

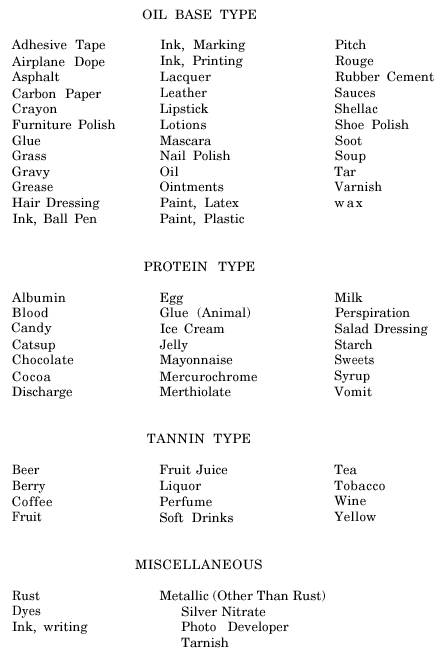

Table 6-2.- Basic Stain Groups

specialized art in which a spot or stain is identified and

removed using the proper chemical agent without damaging or

affecting the clothing. Aboard ship, basic spotting chemical

preparations, which we will discuss later, should be used for

removing stains contained in the basic stain groups shown in table

6-2. Stains are easier to remove when they are fresh and, therefore,

early identification is essential.

THE SPOTTER

The person who does the actual spotting is called the spotter.

The spotter's job is to identify the substance that caused the spot

or stain and to know what cleaning agents and type of treatment to

use to remove it. Many of the fabrics the spotter handles are

expensive. Serious damage to any of them means financial loss as

well as inconvenience to the owner. Therefore, the spotter should

know before trying to remove a spot or stain that the substance and

methods to be used will not destroy the fabric or ruin its

appearance. When in doubt about whether a spot or stain can be

removed without serious damage to the material, the spotter should

contact the supervisor and obtain his or her advice before starting

the work. We have indicated earlier that identification and

treatment of some spots are necessary to keep them from becoming

stains. This is not always possible due to heavy workloads and lack

of time to check clothing items. In this case a note should be

placed in the plan of the day (POD) by the supply officer asking the

owners of articles requiring spotting to tag the articles with a

note identifying the spots. This information makes the spotter's job

easier, faster, and more accurate. It also alerts the spotter to do

spotting before dry cleaning.

SPOTTING TOOLS AND EQUIPMENT

The spotter must know and understand the equipment and tools

used in spotting operations in order to get the best possible

results. Spotting tools and equipment consist of the spotting board

assembly- main spotting board, sleeveboard, garment tray, chemical

tray, and spotting gun; spotting brushes; spatula; chamois and

towels; cheesecloth and blotters; magnifying glass; soap solution

containers; and spotting bottles and agents.

Main Spotting Board

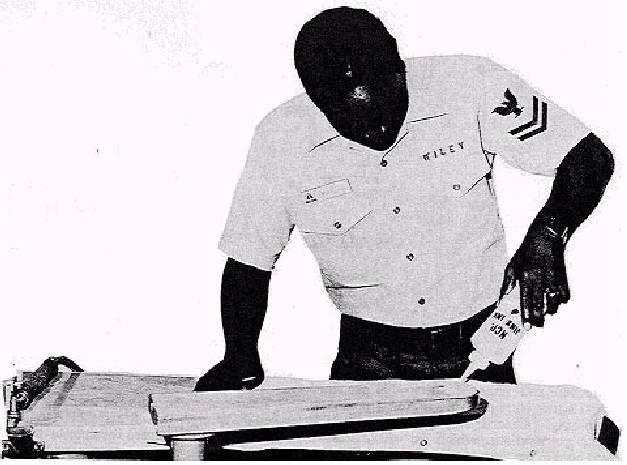

The main spotting board is the spotter's worktable. (See fig.

6-15.) It is shaped like an

Figure 6-15.-Spotter using the spotter board.

ironing board to provide large and small work spaces for articles

of different sizes. The board is usually a combination of a smooth

area and a perforated or screened area. The smooth surface is hard

and usually made of glass, marble, or Monel metal, all of which are

resistant to alkalies and acids. The smooth area is used for tamping

and for applying spotting agents. The perforated or screened area is

used for flushing. The perforated area must be taken apart and

steam-cleaned each day to remove excess chemicals or dyes.

Sleeveboard

The sleeveboard is mounted about 6 inches above the level of the

main spotting board. The sleeveboard, like the main spotting board,

also has a flushing and tamping area. The sleeveboard is attached to

the main board by a movable arm that can be adjusted. This board is

used when working out stains on sleeves and other small areas. Clean

the sleeveboard in the same manner as the main spotting board.

Garment Tray

The garment tray is under the main spotting board, midway

between the board and the floor. The tray must always be clean;

otherwise, the garment resting in it will be soiled.

Chemical Tray

All the basic spotting agents are placed on the chemical tray.

Spotting Gun

The spotting gun is used for removing spots or stains from wool,

silk, and synthetics. The gun is adjusted so that slight pressure on

the steam pedal provides steam and more pressure provides hot water

or wet steam. If compressed air is piped to the spotting board, it

will come through the gun when the appropriate foot pedal is

depressed. When vacuum is piped to the spotting board, it is

controlled by a foot pedal. However, the vacuum is piped to the

perforated area of the board to dry and hold the garment in place

while spotting. The spotting gun must be held about 4 inches above

the garment. If the gun is held closer than 4 inches from the

fabric, the steam or air pressure at 70 to 80 pounds per square inch

can cause permanent damage to the fabric. The spotting gun should be

held perpendicular when blowing the chemicals or spots off a

garment. Before using the spotting gun, point it toward the deck and

depress the steam pedal to remove excess condensation. The spotting

gun must be cleaned daily and all chemicals removed from the nozzle.

Spotting Brushes

Spotting brushes help break up stains so that spotting agents

can penetrate into and around the stains. When the spotting brush is

not being used, the bristles should be pointed downward to allow the

agents to drain from the bristles. The brush can also be placed in

the brush holder to obtain similar results. When the brushes are

used for tamping, the bristles should hit the fabric flat to prevent

damaging the fabric. Never brush or scrub the spot. Spoting brushes

usually come in two sizes (2-inch and 3-inch) and two colors (black

and white) and are made of nylon bristles. The large brush is used

mainly on woolens and synthetics because the bristles are spread far

apart. The small brush has a close set of bristles and is effective

on silk. The black-bristled brush is used for dry-side spotting and

for dark-colored fabrics. The white-bristled brush is used for

wet-side spotting and light-colored fabrics. After a brush is used

on a garment, clean the brush with the spotting gun.

Spatula

The spatula is made of stainless steel, bone, or ivory and is

about 1 inch wide and 5 inches long. The spatula is usually pointed

on one end and rounded at the other end and is used to manipulate

chemicals, soften the stain, and to get better penetration. The

pointed end should not be used because it will dig into the fabric

and distort it. The rounded end should be used for better results.

After each use the spatula should be cleaned.

Chamois and Towels

A thick, heavy chamois is used for absorbing water and spotting

solutions as they are removed from fabrics. The chamois should be

spread smoothly over the portion of the spotting board being used. A

medium-weight Turkish towel serves the same purpose. chemicals,

particularly prevents pitting of the By absorbing cleaning acids,

the absorbent spotting board. Keep chamois cloths or Turkish towels

available for this purpose.

Cheesecloth and Blotters

Cheesecloth, because it is soft and absorbent, is used in

spotting or feathering out- picking up all the moisture around a

spot just removed. This prevents rings from forming. Chamois,

because of its heavy texture, is not good for feathering out. You

can use blotters for absorbing materials rinsed from the garment.

You can also use them to test the resistance of dyes in fabrics to

cleaning chemicals and/ or spotting agents. Put a small portion of

fabric on a blotter and apply the chemical or spotting agent. The

amount of coloring matter dissolved by the chemical and absorbed by

the blotter indicates the effect of the chemical on the dye.

Magnifying Glass

When in doubt about the substance that caused a spot or stain, a

spotter may examine it under a magnifying glass. Although an

inex-perienced spotter may get few results with a magnifying glass

at first, through practice the spotter will learn to identify

various substances as they appear when magnified. The magnifying

glass is used to observe the weave and imperfections of the fabric

and to determine if a discoloration on the garment is a spot or

damaged fibers. It helps to determine the kind of spot or stain and

to observe the action of the spotting chemical. The glass can also

be used to determine whether a spot has a staining substance or

whether the spot has a chafed area with loss of dye. The magnifying

glass will help you determine if the stained area is too weak to

stand treatment and if a spot on a synthetic fabric was caused by

heat damage.

Soap Solution Containers

Usually each spotting board has two con-tainers to hold soap

solutions. The containers should be cleaned daily.

Spotting Bottles and Agents

Spotting bottles and chemical agents are held in a tray at the

right end of the spotting board. Dropper bottles with ground glass

stoppers and rubber bulk pipettes are preferred. These types of

bottles control the chemicals and conserve materials. However, on

board ship, squeeze-type containers with a dropper top have been

found to be more convenient and satisfactory from the standpoint of

handling and breakage. The chemical agents commonly used to remove

spots and stains are listed in table 6-3. Their characteristics and

uses are given, and also the precautions you should take with them. |